- +1 (510) 365-3338

- +1 5103653338

- evan@commmesh.com

- +86 15274842581

You need fast connections. Our pre-terminated fiber optic cable assemblies deliver just that. Cables feature 250 µm bare fiber, removing field termination complexities.

A 900 µm tight-buffered fiber setup offers protection, supporting 10 Gbps data. Expect low signal loss, with 0.3 dB maximum insertion loss. You will get a 50 dB return loss, too. A PVC outer jacket, plus aramid yarn, adds durability. Assemblies are rated for OFNR (riser) use.

These offer 2 mm duplex fiber cords, enabling 1000 mating cycles. Operating temperature of cables is -20 °C to 70 °C. Bend-insensitive fiber reduces signal loss in tight spaces. You get a 3 mm yellow, single-mode patch cord. These use LC connectors with 1.25 mm ferrules.

Choose OS2, OM1, OM3, OM4, or OM5 fiber. Also, 4.8 mm fiber channel tech is available. Assemblies meet the fiber optic connector intermate-ability standard (FOCIS). Wavelengths of 1310 nm or 1550 nm are used.

Lengths are customized for our pre-terminated fiber optic cable assemblies, starting at 1 meter. Also, we provide single-mode (OS2) or multimode (OM1, OM3, OM4, and OM5) fibers. You can ask for a 9/125 µm core or a 50/125 µm size. Moreover, each assembly is configured as a 6-fiber or 12-fiber count. Our cables utilize 7.9 mm low-smoke, zero-halogen materials.

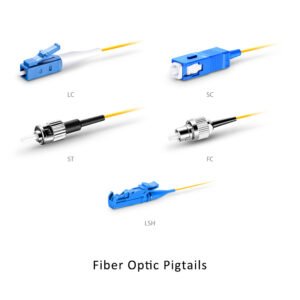

Connectors can be chosen. These assemblies could be SC, LC or ST, for example. Or, you could prefer FC or MTP. Further, we offer UPC or APC polish finishes. Some connectors get 2.5 mm ferrules. While others have 1.25 mm ones. As a matter of fact, insertion loss goes as low as 0.1 dB. Furthermore, operating temperatures range from -40°C up to 85°C.

Breakout-style pre-terminated fiber optic cable assemblies are available with 250 µm or 900 µm legs, including options for 2 to 144 fibers. Also, furcation tubing is offered. Consequently, pulling eyes can be used during setup. Additionally, assemblies are made with 3.0 mm zipcord cable. All options ensure easy handling. Finally, fan-out kits come in varied lengths.

Labels can be customized on our pre-terminated fiber optic cable assemblies. You might specify sequential numbers, or at least unique identifiers. In addition to that, barcodes, QR codes, or text labels can be chosen. Different colors help with organization. Meanwhile, font sizes can be selected. Specifically, tags can go on each end or along the jacket. Ultimately, every label is made to last.

| Specification | Fiber Types | Connector Types | Jacket Material | Loss Specs | Temp Range (°C) | Fiber Specs |

| Core Diameter | 9/125 µm, 50/125 µm | LC, SC, MTP | PVC, LSZH, PE | 0.1 dB, 0.3 dB | -55 to 85 | OS2, OM5 |

| Fiber Count | 6, 12, 24, 144 | UPC, APC Polish | Armored, Tactical | 50 dB Return | -40 to 85 | G.657.A1, G.652.D |

| Wavelength (nm) | 850, 1310, 1550 | 1.25 mm, 2.5 mm | OFNR, OFNP | 0.35 dB, 0.75 dB | -20 to 70 | 250 µm, 900 µm |

| Tensile Strength | 220 N, 445 N | Simplex, Duplex | Plenum, Riser | 0.5 dB Max | -40 to 70 | Bend-insensitive |

| Mating Cycles | 500, 1000 | E2000, MPO | UV-Resistant | GR-326 Compliant | 0 to 60 | 2 mm, 4.8 mm |

| Standard Compliance | FOCIS, TIA-568 | Metal, Plastic | Dry-block, Gel | ANSI/TIA-568 | -20 to 60 | 10 Gbps, 40 Gbps |

| Cable Length | 1 m, 300 m | Push-Pull, Lock | Indoor, Outdoor | OTDR Tested | -40 to 85 | 7.9 mm, 3.0 mm |

Installation is easy with our pre-terminated fiber optic cable assemblies. Since connectors are factory-installed, you save time. Standard patch panels work well with these. Connecting takes just seconds. Also, each connector is rated for 500 or more uses. Insertion loss is typically better than 0.75 dB for multimode. Yet, single-mode insertion loss remains under 0.35 dB.

Features such as Pre-terminated Fiber Optic Cable Assemblies reduces management from the color-coded jacket. They reduce the clutter in such crowded spaces. While Velcro straps help with organization, you can also use existing paths. Bend radiuses can be as small as 10 times the diameter. Because of this, installation in tight spots is simpler. Airflow improves, and heat reduces.

Errors are minimized with these pre-terminated fiber optic cable assemblies, thanks to factory testing. Because of quality checks, polarity problems are rare. Using a 400x microscope, each connector end is checked. While interferometry confirms the shape, the loss values stay below 0.5 dB. Also, return loss is better than -55 dB. Reports are provided, and they meet ANSI/TIA-568 rules.

Pre terminated fiber optic cable assemblies are faster to deploy. For example, businesses use these to link servers, it saves time. You might also connect distribution points. Each part supports Ethernet, Fibre Channel, or InfiniBand; although, network uptime is improved. Cables lower labor needs, require no special tools, and meet IEEE 802.3ba standards. Your installers can also attach them to media converters.

Quick Contact

To save your time, please contact us quickly via the form below to get an instant quote.