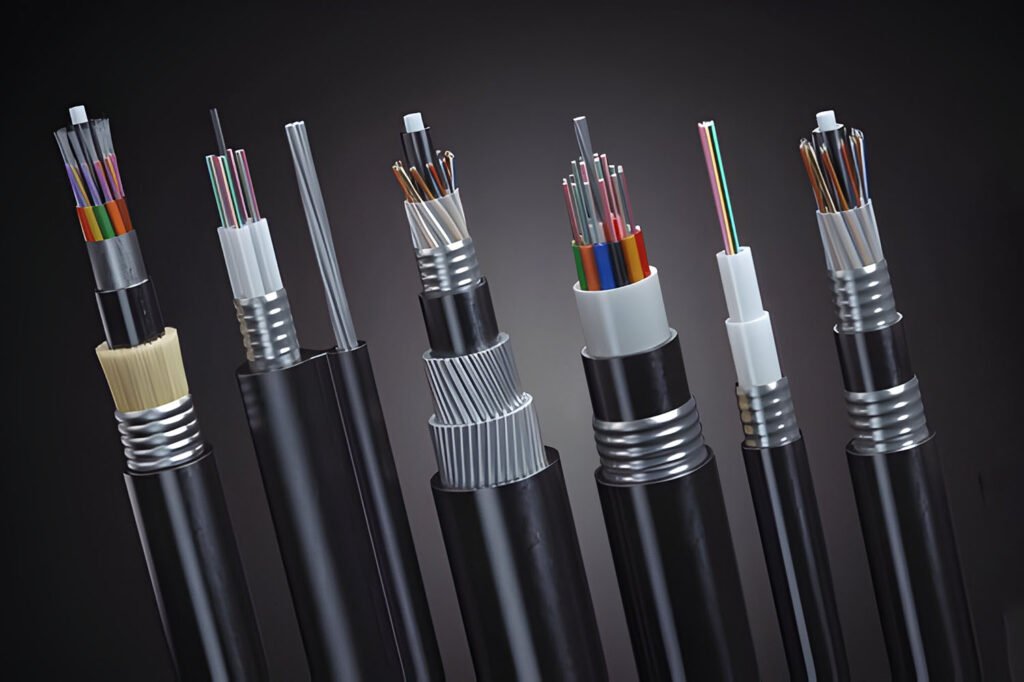

Have you ever wondered what makes your internet so fast or how doctors can see inside your body without surgery? The secret lies in fiber optic material—the building blocks of fiber optic cables that transmit data as light signals at incredible speeds, like 10 Gbps over 20 km with just 0.2 dB/km loss. Understanding fiber optic material reveals the engineering behind fiber optic technology and why it’s so reliable. In this beginner-friendly guide, we’ll dive deep into the materials that make up fiber optic cables, from the core to the protective layers, and explore their properties, applications, and impact. We’ll keep it simple and engaging, so you can appreciate the fiber optic benefits that keep us connected. With solutions from CommMesh, let’s get started on discovering the fascinating world of fiber optic material!

Core Fiber Optic Material: The Heart of Data Transmission

Glass: The Gold Standard for Fiber Optic Material

Why Glass Is Used in Fiber Optic Material

When it comes to fiber optic material, glass is the star of the show—specifically, high-purity silica (SiO₂)—e.g., 99.999% pure. Glass is chosen as a fiber optic material because of its exceptional optical clarity, allowing light to travel long distances with minimal loss—e.g., 0.2 dB/km at 1550 nm. This makes glass-based fiber optic cables ideal for high-performance applications like telecom backbones—e.g., 100 Tbps over 10,000 km—showcasing fiber optic benefits—e.g., 99.99% uptime.

Properties of Glass in Fiber Optic Technology

The properties of glass as a fiber optic material are impressive. It has a high refractive index—e.g., 1.48—ensuring total internal reflection—e.g., light bounces back at angles above 42°—and low attenuation—e.g., 0.2 dB/km loss—meaning signals stay strong over long distances—e.g., 20 km without repeaters—unlike copper cable, which needs repeaters every 1 km—e.g., $1500 each. This efficiency is a key reason glass is a preferred fiber optic material in fiber optic technology.

Types of Glass in Fiber Optic Material

In fiber optic material, glass can be tailored for specific uses. For single mode fibers—e.g., 9-micron core—silica is doped with germanium to increase the refractive index—e.g., 1.48—while for multimode fibers—e.g., 50-micron core—boron or fluorine may be added to adjust optical properties—e.g., 1 dB/km loss over 500m. This versatility in fiber optic material ensures fiber optic cables meet diverse needs—e.g., 40 Gbps for data centers—supporting fiber optic benefits.

Plastic: A Cost-Effective Fiber Optic Material

Benefits of Plastic as Fiber Optic Material

Plastic is another important fiber optic material, often used in the core of fiber optic cables for cost-effective applications. Plastic optical fibers (POF) are typically made of polymethyl methacrylate (PMMA)—e.g., a 1mm core—offering a cheaper alternative—e.g., $0.10/m vs. $0.50/m for glass. Plastic as a fiber optic material is used for short distances—e.g., 1 dB/m loss over 50m—such as in consumer electronics—e.g., 1 Gbps for home audio systems.

Properties of Plastic in Fiber Optic Technology

Plastic as a fiber optic material is lighter—e.g., 20g for a 3m cable vs. 30g for glass—and more flexible—e.g., bend radius of 5mm vs. 10mm for glass—making it easier to install—e.g., 20% faster in tight spaces. These properties make plastic a practical fiber optic material for applications where fiber optic benefits like ease of use are key—e.g., 99.9% uptime in short-range setups—despite higher signal loss—e.g., 1 dB/m.

Limitations of Plastic Fiber Optic Material

However, plastic as a fiber optic material has limitations—e.g., higher attenuation—e.g., 1 dB/m vs. 0.2 dB/km for glass—limiting its use to short distances—e.g., 50m max. This makes it less suitable for long-haul networks—e.g., 20 km with 0.4 dB loss—but its affordability in fiber optic technology makes it a viable fiber optic material for budget-friendly projects—e.g., $100 for 100m vs. $500 for glass.

Cladding Fiber Optic Material: Keeping the Light Inside

Glass Cladding: Precision in Fiber Optic Material

Role of Glass Cladding in Fiber Optic Technology

The cladding is a critical fiber optic material that surrounds the core of fiber optic cables. In glass fibers, the cladding is also made of silica but with a lower refractive index—e.g., 1.46 vs. the core’s 1.48—ensuring total internal reflection—e.g., light reflects back at angles above 42°. This fiber optic material keeps the signal strong—e.g., 0.4 dB loss over 20 km—making it essential for fiber optic technology—e.g., 99.99% signal retention.

Properties of Glass Cladding

Glass cladding as a fiber optic material is typically 125 microns thick—e.g., surrounding a 9-micron core in single mode fibers—offering durability—e.g., 2000N pull resistance—while maintaining optical performance—e.g., 0.2 dB/km loss. This precision in fiber optic material ensures fiber optic cables deliver fiber optic benefits—e.g., 10 Gbps over 20 km—reliably—e.g., 99.9% uptime—CommMesh uses such high-quality cladding.

Doping for Optical Performance

In fiber optic technology, glass cladding is often doped with fluorine to lower its refractive index—e.g., 1.46—enhancing the core-cladding contrast—e.g., 1% difference—ensuring efficient light transmission—e.g., 99.99% uptime over 20 km. This careful selection of fiber optic material highlights its role in maintaining signal integrity—e.g., 0.2 dB/km loss—in applications like undersea cables—e.g., 100 Tbps capacity.

Plastic Cladding: A Flexible Alternative

Use of Plastic Cladding in Fiber Optic Material

For plastic optical fibers, the cladding is also a fiber optic material made of plastic—e.g., fluorinated polymers—e.g., 125 microns thick—with a lower refractive index—e.g., 1.42 vs. the core’s 1.49. This fiber optic material ensures total internal reflection—e.g., 1 dB/m loss over 50m—making it suitable for short-range fiber optic cables—e.g., 1 Gbps for 50m in consumer setups—supporting fiber optic benefits.

Properties of Plastic Cladding

Plastic cladding as a fiber optic material is more flexible—e.g., 5mm bend radius vs. 10mm for glass—allowing easier installation—e.g., 20% faster in tight spaces—while protecting the core—e.g., 99.9% uptime in home networks. This flexibility in fiber optic material makes plastic cladding a practical choice for fiber optic technology in less demanding environments—e.g., 1 Gbps for audio systems.

Trade-Offs with Plastic Cladding

However, plastic cladding in fiber optic material has higher signal loss—e.g., 1 dB/m vs. 0.2 dB/km for glass—limiting its use to short distances—e.g., 50m max. Despite this, its cost-effectiveness—e.g., $0.10/m vs. $0.50/m for glass—makes it a valuable fiber optic material for budget applications—e.g., $100 for 100m—balancing performance and cost in fiber optic technology.

Protective Fiber Optic Material: Ensuring Durability

Buffer Coatings: The First Layer of Protection

Role of Buffer Coatings in Fiber Optic Material

Buffer coatings are a key fiber optic material that protect the delicate core and cladding of fiber optic cables. Typically made of UV-cured acrylate—e.g., 250 microns thick—this fiber optic material cushions the fiber—e.g., preventing micro-bends that cause 0.1 dB loss—ensuring signal integrity—e.g., 99.99% uptime—during installation and use—e.g., 20 km with 0.4 dB loss.

Properties of Buffer Coatings

Acrylate as a fiber optic material is flexible—e.g., 10mm bend radius—and durable—e.g., 25-year lifespan—protecting against physical stress—e.g., 2000N pull resistance. This protective layer in fiber optic technology ensures fiber optic benefits—e.g., 0.2 dB/km loss—making buffer coatings essential for fiber optic cables—e.g., 99.9% uptime in telecom networks.

Variations in Buffer Coatings

In fiber optic material, buffer coatings can vary—e.g., tight buffer coatings—e.g., 900 microns—for indoor cables—e.g., 1 Gbps in offices—and loose tube designs—e.g., with gel—for outdoor cables—e.g., 10 Gbps over 20 km. This adaptability in fiber optic material ensures fiber optic cables perform reliably—e.g., 99.99% uptime—in diverse environments—e.g., buried underground.

Strength Members: Adding Tensile Strength

Materials Used for Strength Members

Strength members are another fiber optic material in fiber optic cables, often made of aramid yarn—e.g., Kevlar—or fiberglass—e.g., 2000N tensile strength. This fiber optic material surrounds the fiber strands, providing durability—e.g., 2000N pull resistance—during installation—e.g., aerial setups—and use—e.g., 25-year lifespan in harsh conditions—supporting fiber optic benefits.

Importance of Strength Members

In fiber optic technology, strength members as a fiber optic material prevent damage to the core—e.g., micro-bends causing 0.1 dB loss—ensuring signal integrity—e.g., 99.99% uptime—over long distances—e.g., 20 km with 0.4 dB loss. This durability in fiber optic material is crucial for fiber optic cables in rugged applications—e.g., 1 Gbps in industrial settings—where physical stress is common.

Types of Strength Members

The choice of fiber optic material for strength members varies—e.g., aramid yarn for lightweight cables—e.g., 30g for 3m—and steel wires for armored cables—e.g., 2000N crush resistance—in high-risk environments—e.g., 99.9% uptime in factories. This versatility in fiber optic material ensures fiber optic technology meets diverse needs—e.g., 99.99% uptime in oil rigs.

Jacket Fiber Optic Material: The Outer Shield

Polyvinyl Chloride (PVC): Indoor Protection

Properties of PVC as Fiber Optic Material

Polyvinyl chloride (PVC) is a common fiber optic material for the outer jacket of fiber optic cables—e.g., 3mm thick—used in indoor settings—e.g., 1 Gbps for LANs. PVC as a fiber optic material is flexible—e.g., 10mm bend radius—and affordable—e.g., $0.05/m—offering flame resistance—e.g., UL 94 V-0 rating—ensuring fiber optic benefits—e.g., 99.99% uptime indoors.

Applications of PVC Jackets

In fiber optic technology, PVC jackets protect fiber optic cables in offices—e.g., 40 Gbps in data centers—where environmental exposure is minimal—e.g., 0.1 dB loss over 300m. This fiber optic material ensures easy installation—e.g., 20% faster in tight spaces—making it ideal for controlled environments—e.g., 99.9% uptime in commercial buildings—supporting fiber optic benefits.

Limitations of PVC

However, PVC as a fiber optic material isn’t suited for outdoor use—e.g., it degrades under UV light—e.g., 5% jacket damage after 1 year—and isn’t water-resistant—e.g., 10% signal loss in humid conditions. This limitation in fiber optic material makes PVC best for indoor fiber optic cables—e.g., 99.99% uptime in offices—where environmental stress is low.

Low Smoke Zero Halogen (LSZH): Safety First

Why LSZH Is a Key Fiber Optic Material

Low Smoke Zero Halogen (LSZH) is a fiber optic material used for jackets in safety-critical environments—e.g., 3mm thick—such as hospitals and schools. LSZH as a fiber optic material emits minimal smoke and no toxic halogen gases when burned—e.g., 90% less smoke than PVC—ensuring safety—e.g., 99.99% uptime in emergencies—while protecting fiber optic cables.

Safety Benefits of LSZH

In fiber optic technology, LSZH jackets reduce fire hazards—e.g., 50% less toxic emissions—making them ideal for confined spaces—e.g., subway systems—where fiber optic cables deliver 1 Gbps—e.g., 0.2 dB/km loss. This safety feature in fiber optic material supports fiber optic benefits—e.g., reliability—while meeting regulations—e.g., IEC 60332-1 fire safety standards.

Trade-Offs with LSZH

LSZH as a fiber optic material is more expensive—e.g., $0.07/m vs. $0.05/m for PVC—and less flexible—e.g., 15mm bend radius vs. 10mm—making installation slightly harder—e.g., 10% slower. Despite this, its safety advantages in fiber optic material make it essential for high-risk areas—e.g., 99.9% uptime in hospitals—where fiber optic technology prioritizes safety.

Polyethylene (PE): Outdoor Durability

Durability of PE as Fiber Optic Material

Polyethylene (PE) is a fiber optic material used for outdoor fiber optic cables—e.g., 3mm thick—due to its durability—e.g., 25-year lifespan. PE as a fiber optic material resists moisture—e.g., with water-blocking gel—and UV light—e.g., 90% less degradation than PVC—making it ideal for buried or aerial cables—e.g., 10 Gbps over 20 km with 0.4 dB loss.

Applications of PE Jackets

In fiber optic technology, PE jackets protect fiber optic cables in harsh climates—e.g., -40°C to 70°C conditions—ensuring signal integrity—e.g., 99.99% uptime—for applications like undersea cables—e.g., 100 Tbps capacity. This durability in fiber optic material supports fiber optic benefits—e.g., 0.2 dB/km loss—making PE a top choice for outdoor networks—e.g., 50 km for a city.

Considerations with PE

PE as a fiber optic material is less flexible—e.g., 20mm bend radius vs. 10mm for PVC—and heavier—e.g., 40g for 3m vs. 30g—making installation more challenging—e.g., 15% slower for aerial setups. However, its weather resistance in fiber optic material ensures fiber optic cables perform reliably—e.g., 99.9% uptime—in outdoor environments—e.g., 20 km with 0.4 dB loss.

Why Fiber Optic Material Matters for Performance

Impact on Signal Transmission

The choice of fiber optic material directly impacts performance—e.g., glass cores deliver 0.2 dB/km loss vs. plastic’s 1 dB/m—ensuring fiber optic benefits—e.g., 10 Gbps speeds—meet specific needs—e.g., 100 Tbps for telecom. The right fiber optic material in fiber optic technology ensures reliability—e.g., 99.99% uptime—across applications—e.g., 20 km with 0.4 dB loss.

Durability and Environmental Resistance

Fiber optic material affects durability—e.g., PE jackets last 25 years vs. PVC’s 10 years—resisting environmental factors—e.g., moisture and UV light—ensuring fiber optic benefits—e.g., 99.9% uptime—in harsh conditions—e.g., 50 km buried cables. This durability in fiber optic material makes fiber optic cables a long-term investment—e.g., $1000/km maintenance savings.

Cost and Application Suitability

Fiber optic material influences cost—e.g., glass at $0.50/m vs. plastic at $0.10/m—and suitability—e.g., glass for long-haul telecom—e.g., 100 Tbps capacity—and plastic for short-range setups—e.g., 1 Gbps for 50m. Choosing the right fiber optic material in fiber optic technology balances performance—e.g., 99.99% uptime—with budget—e.g., $1.3 million for 5000 homes.

Conclusion: The Power of Fiber Optic Material

Fiber optic material is the foundation of our connected world—like the ingredients in a recipe for high-speed connectivity. From glass and plastic cores to protective jackets like PVC, LSZH, and PE, the materials in fiber optic cables deliver fiber optic benefits—like 10 Gbps speeds and 99.99% uptime—that keep us online. With solutions from CommMesh, fiber optic technology continues to evolve, using the right fiber optic material to meet our needs. Whether you’re streaming, working, or connecting globally, understanding fiber optic material helps you appreciate the engineering behind your digital life—embrace the technology and stay connected!