In the high-stakes world of fiber optic networking, where every decibel of loss, every millisecond of latency, and every port of density directly impacts performance, cost, and scalability, one of the most fundamental decisions remains the choice between SC and LC fiber connectors.

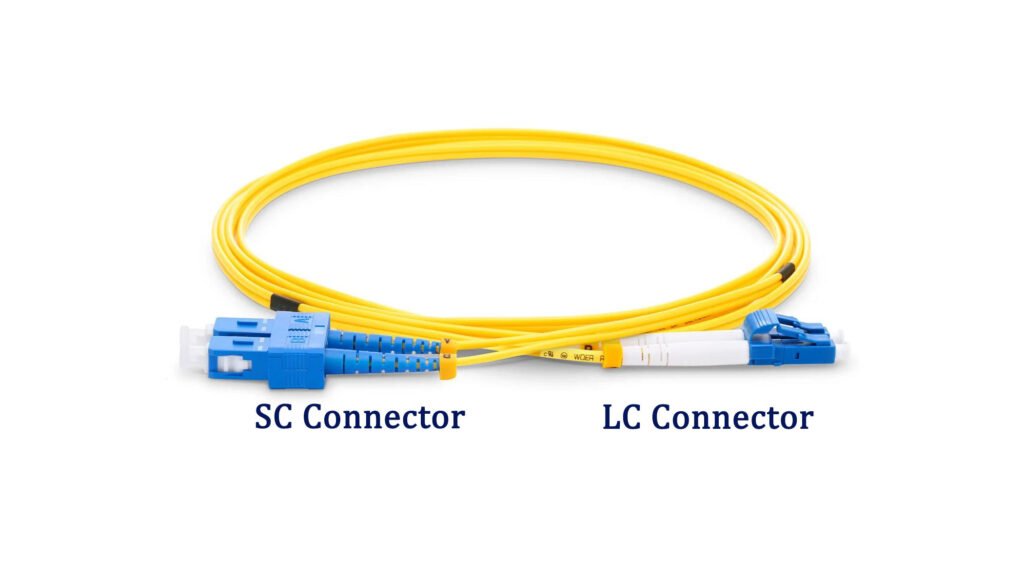

SC (Subscriber Connector) and LC (Lucent Connector, also called Little Connector) are the two dominant connector types powering modern networks—from FTTH drops and PON infrastructure to hyperscale data centers running 800G and 1.6T Ethernet. As of January 2026, with global fiber connections exceeding 2.5 billion and high-density architectures pushing physical limits, understanding SC vs LC fiber connectors is essential for network architects, engineers, procurement teams, installers, and operators.

This exhaustive guide provides the most comprehensive comparison of SC vs LC fiber connectors available. We cover their history and evolution, physical and mechanical design differences, optical performance metrics, density and space efficiency, real-world applications across industries, installation and handling considerations, polarity management, cost analysis, compatibility and migration strategies, common myths debunked, emerging trends for 2026–2030, and a practical decision framework.

Authored by CommMesh — a Tier-1 manufacturer producing both SC and LC assemblies for telecom operators — this article delivers unbiased, data-driven insights to help you select the optimal connector for your current and future networks.

1. Historical Background and Evolution of SC and LC Connectors

1.1 The Birth of SC: The Subscriber Connector Revolution

Developed by Japanese telecom giant NTT in the mid-1980s, the SC connector was designed as a robust, easy-to-use alternative to the threaded FC connector. Its push-pull mechanism, 2.5 mm ceramic ferrule, and square housing made it ideal for high-volume telecom deployments.

Key milestones for SC:

- Late 1980s: First commercial use in Japanese telecom networks.

- 1990s: Becomes global standard for central offices and early FTTH trials.

- 2000s: SC/APC (angled polish) dominates PON and CATV due to superior return loss.

- 2010s–2020s: Remains the preferred connector for outside plant (OSP) in FTTH, especially drop cables and ONT terminations.

- 2026 status: Still the most common connector in global FTTH installations (estimated 55% market share in OSP).

The SC’s larger size and rugged design made it perfect for field technicians working in manholes, aerial splices, and customer premises.

1.2 The Rise of LC: The Density Champion

Invented by Lucent Technologies (now Nokia) in the late 1990s, the LC connector addressed the growing need for higher port density. By halving the ferrule diameter to 1.25 mm and using an RJ45-style latch, LC enabled twice the connections in the same space.

Key milestones for LC:

- Late 1990s: Introduced with SFP transceivers.

- Early 2000s: Rapid adoption in enterprise and data center switching.

- 2010s: Becomes standard for 40G/100G QSFP breakouts and high-density panels.

- 2020s: Dominant in 400G/800G QSFP-DD and OSFP modules; uniboot and quad designs emerge.

- 2026 status: Controls ~70% of data center and high-speed interconnect market.

LC’s small form factor revolutionized panel density and transceiver design.

1.3 The Ongoing SC vs LC Debate in 2026

While LC has largely won the density battle, SC maintains strong positions in legacy telecom, FTTH OSP, and applications requiring ruggedness. Hybrid networks using both are common, creating demand for SC-LC hybrid patch cords.

The choice affects:

- Port density and rack space

- Installation speed and technician skill

- Maintenance and troubleshooting

- Upgrade path to higher speeds

2. Physical Design and Mechanical Comparison

2.1 Size and Footprint

- SC: 2.5 mm ferrule, ~13 mm wide housing

- LC: 1.25 mm ferrule, ~6.25 mm wide (half SC footprint)

LC enables 2× density in panels and 4× with quad adapters.

2.2 Coupling Mechanism

- SC: Push-pull (insert and pull collar)

- LC: Latch (press tab like RJ45)

SC is more forgiving in dirty/gloved environments; LC latch can break if mishandled.

2.3 Duplexing

- SC: Separate duplex clip

- LC: Integrated duplex housing or uniboot designs

LC uniboot allows polarity flip without tools.

2.4 Ferrule and Polish

Both use zirconia ferrules with:

- UPC (flat, blue housing): ≥50–55 dB return loss

- APC (8° angle, green housing): ≥60–65 dB return loss

No inherent performance difference in polish quality.

2.5 Durability and Mating Cycles

- Both rated 500–1000 matings

- SC’s larger size resists damage better in field

- LC more susceptible to latch failure

3. Optical Performance: Head-to-Head Metrics

| Parameter | SC Connector (Premium) | LC Connector (Premium) | Notes |

|---|---|---|---|

| Insertion Loss (typical) | 0.10–0.20 dB | 0.10–0.20 dB | Identical |

| Insertion Loss (max) | ≤0.30 dB | ≤0.30 dB | |

| Return Loss UPC | ≥55 dB | ≥55 dB | |

| Return Loss APC | ≥65 dB | ≥65 dB | APC mandatory for PON |

| Repeatability | ≤0.1 dB (1000 matings) | ≤0.1 dB (1000 matings) | |

| Temperature Stability | Excellent | Excellent |

Performance is essentially the same when manufactured to high standards.

4. Density and Space Efficiency: LC’s Biggest Advantage

4.1 Patch Panel Density

- SC: 24–48 ports per 1U panel

- LC: 96–144 ports per 1U (standard duplex)

- Quad LC: Up to 576 ports per 1U

In 800G data centers, LC density saves millions in real estate.

4.2 Transceiver Impact

- SFP/SFP+: LC duplex

- QSFP28/QSFP-DD/OSFP: LC breakouts or MPO

LC enables smaller, higher-density modules.

4.3 Cable Management

LC’s smaller footprint simplifies routing in crowded trays.

5. Applications: Where SC and LC Excel in 2026

5.1 SC Connector Applications

- FTTH Outside Plant: SC/APC pigtails in fiber optic closures, drop cables to ONT.

- CATV/RFoG: SC/APC for analog video overlay.

- Telecom CO/Headend: Legacy SC panels.

- Industrial/Harsh Environments: Rugged SC for factories, oil rigs.

5.2 LC Connector Applications

- Data Centers: High-density panels, transceivers (SFP, QSFP).

- Enterprise LAN: LC for switch uplinks.

- Hyperscale DCI: 400G/800G breakout to LC.

- Campus Networks: Compact LC patching.

5.3 Hybrid Use Cases

Many operators use SC/APC in OSP and LC in data centers, requiring SC-LC hybrid cords.

6. Cost Analysis 2026

| Item (duplex, 3m, single-mode) | SC Price | LC Price | Notes |

|---|---|---|---|

| OS2 UPC | $3.20–$5.00 | $2.50–$4.20 | LC cheaper at scale |

| OS2 APC | $3.80–$5.80 | $3.00–$4.80 | APC premium ~10% |

| Multimode OM4 | $4.50–$6.50 | $3.50–$5.50 | |

| Bulk pigtail (12-pack) | $22–$32 | $18–$28 |

LC’s manufacturing scale and smaller size drive 10–20% lower costs.

7. Installation and Handling Considerations

7.1 Ease of Use

- SC: Larger, easier to grip with gloves; push-pull forgiving.

- LC: Smaller latch requires dexterity; prone to breakage if mishandled.

7.2 Cleaning and Inspection

Both require meticulous cleaning, but LC’s smaller ferrule makes contamination harder to spot without high-magnification scopes.

Best practice: IEC 61300-3-35 compliant inspection.

7.3 Polarity Management

- SC: Fixed polarity; requires keyed adapters for Type B.

- LC: Uniboot or flipable designs allow field polarity change.

LC offers greater flexibility.

8. Compatibility, Migration, and Hybrid Strategies

- SC to LC hybrid patch cords common for transitions.

- Adapters available but add ~0.5 dB loss and failure points.

Best strategy: Standardize on LC for new builds, maintain SC for legacy OSP.

9. Myths and Misconceptions Debunked

Myth 1: “SC is more reliable than LC”

Reality: Reliability depends on manufacturing quality, not size.

Myth 2: “LC has higher insertion loss”

Reality: Identical when properly made.

Myth 3: “You can’t use LC in outdoor environments”

Reality: Ruggedized LC (hardened adapters) common in FTTH.

Myth 4: “SC is obsolete”

Reality: Still dominant in global FTTH OSP (estimated 1.4 billion SC/APC connections).

Myth 5: “APC is only for video”

Reality: APC mandatory for all PON to prevent reflection interference.

10. Future Trends in SC and LC Connectors 2026–2030

10.1 LC Evolution

- Uniboot, push-pull LC for easier handling

- Quad LC and very small form factor (VSFF) like SN/MDC challenging LC in ultra-density

- LC in co-packaged optics roadmaps

10.2 SC Persistence

- Continued dominance in FTTH OSP

- Hardened SC for 5G fronthaul

10.3 Overall Shift

Density demands will push LC (and successors) to >80% market share by 2030.

Conclusion: Making the Right Choice in 2026

For new high-density, high-speed deployments (data centers, enterprise, 400G+), LC is the clear winner.

For FTTH outside plant, legacy telecom, or rugged field environments, SC — particularly SC/APC — remains essential.

The optimal modern strategy: Use LC for indoor/high-density, SC/APC for PON OSP, with hybrid cords for transitions.

CommMesh manufactures both with premium performance (≤0.12 dB IL, ≥68 dB RL APC).

Contact us for hybrid assemblies, migration planning, or bulk pricing.

Your network’s reliability starts with the right connector — choose wisely.