في عصرنا الرقمي، يتم تشغيل الإنترنت عالي السرعة وشبكات الاتصالات الموثوقة بواسطة كابلات الألياف الضوئية، التي تنقل البيانات كإشارات ضوئية بسرعات مذهلة. ومع ذلك، فإن أداء تقنية الألياف البصرية يعتمد بشكل كبير على السليم تركيب كابلات الألياف الضوئيةسواء كان الأمر يتعلق بربط المدن أو المباني أو حتى القارات، أو التثبيت كابلات الألياف الضوئية يتطلب تخطيطًا وتنفيذًا دقيقين لضمان الأداء الأمثل والمتانة. تتطلب البيئات المختلفة متطلبات مختلفة. تركيب كابلات الألياف الضوئية الطرق: كابلات هوائية مربوطة على أعمدة، وكابلات مدفونة مباشرة تحت الأرض، وكابلات بحرية ممدودة تحت الماء، وكابلات داخلية أو خارجية تُستخدم في بيئات محددة. سيرشدك هذا الدليل الملائم للمبتدئين خطوة بخطوة خلال عملية تركيب كابلات الألياف الضوئية لكل طريقة، مع تسليط الضوء على أفضل الممارسات والأدوات والاعتبارات. سواء كنت فنيًا أو مخطط شبكات أو مجرد فضولي تقنية الألياف البصريةستساعدك هذه المقالة على فهم كيفية التثبيت كابلات الألياف الضوئية بفعالية. لنبدأ بهذا الدليل الشامل لـ تركيب كابلات الألياف الضوئية!

فهم تركيب كابلات الألياف الضوئية

تركيب كابلات الألياف الضوئية هي عملية النشر كابلات الألياف الضوئية لإنشاء شبكة لنقل البيانات كإشارات ضوئية. في تقنية الألياف البصريةتتكون هذه الكابلات من ألياف زجاجية أو بلاستيكية تحمل نبضات ضوئية، مما يوفر نطاقًا تردديًا عاليًا وزمن وصول منخفضًا ومناعة ضد التداخل الكهرومغناطيسي. تركيب كابلات الألياف الضوئية تتضمن العملية تخطيط المسار، وتجهيز البيئة، ومدّ الكابل، وتوصيله بالمعدات، واختبار الشبكة. هناك طرق مختلفة تركيب كابلات الألياف الضوئية— مثل الحفر الجوي، والدفن المباشر، والحفر تحت الماء، والحفر الداخلي، والحفر الخارجي — تتطلب أساليب مصممة خصيصًا لمراعاة العوامل البيئية، أنواع الكابلات الضوئية، ومتطلبات الأداء، وضمان كابلات الألياف الضوئية العمل بشكل موثوق على مسافات طويلة.

لماذا يُعدّ التركيب السليم أمرًا بالغ الأهمية في تقنية الألياف الضوئية

سليم تركيب كابلات الألياف الضوئية أمر بالغ الأهمية لأداء الشبكة وطول عمرها. في تقنية الألياف البصرية، حتى الأخطاء البسيطة - مثل الأخطاء المفرطة الانحناءأو التوصيل غير السليم أو التعرض للرطوبة - قد يؤدي إلى تدهور جودة الإشارة، مما يؤدي إلى فقدان البيانات أو تعطل الشبكة. على سبيل المثال، قد يؤدي تركيب هوائي غير صحيح كابل الألياف الضوئية قد يتدلى وينكسر في الرياح العاتية، بينما قد يتلف الكابل المدفون بشكل سيئ بسبب الحفر. كل تركيب كابلات الألياف الضوئية تُعالج هذه الطريقة تحدياتٍ مُحددة، مثل حماية الكابلات البحرية من ضغط المياه أو ضمان استيفاء الكابلات الداخلية لمعايير السلامة من الحرائق. باتباع أفضل الممارسات في تركيب كابلات الألياف الضوئيةيمكن للفنيين ضمان اتصالات موثوقة وعالية السرعة لسنوات قادمة.

الأدوات واحتياطات السلامة لتركيب كابلات الألياف الضوئية

قبل البدء بأي شيء تركيب كابلات الألياف الضوئيةيحتاج الفنيون إلى الأدوات المناسبة وإجراءات السلامة. تشمل الأدوات الأساسية قواطع الكابلات، وقواطع التجريد، وقواطع القواطع، وقواطع الوصل الانصهارية، وأجهزة قياس انعكاس المجال الزمني البصري (OTDRs) للاختبار، ومعدات الحماية مثل القفازات ونظارات السلامة. تقنية الألياف البصرية، العمل مع كابلات الألياف الضوئية يتضمن التعامل مع ألياف الزجاج، والتي قد تتفتت وتُسبب إصابات، لذا تُعد احتياطات السلامة أمرًا بالغ الأهمية. يجب على الفنيين أيضًا اتباع اللوائح المحلية، مثل الحصول على تصاريح الحفر في مواقع الدفن المباشر. تركيب كابلات الألياف الضوئية أو التأكد من أن التركيبات الهوائية تلبي متطلبات الارتفاع. يضمن التحضير الجيد عملية سلسة وآمنة تركيب كابلات الألياف الضوئية العملية، بغض النظر عن الطريقة المستخدمة.

دليل خطوة بخطوة لطرق تركيب كابلات الألياف الضوئية

تركيب كابلات الألياف الضوئية الجوية

جوي تركيب كابلات الألياف الضوئية يتضمن تعليق كابلات الألياف الضوئية على الأعمدة أو الأبراج، وهي شائعة الاستخدام في المناطق الحضرية والريفية لشبكات الاتصالات. إليك دليل خطوة بخطوة:

- التخطيط والمساحة: ارسم خريطة للمسار، مع تحديد أعمدة الكهرباء الحالية أو التخطيط لأعمدة جديدة. تحقق من وجود عوائق كالأشجار أو خطوط الكهرباء، واحصل على التصاريح اللازمة. تركيب كابلات الألياف الضوئية.

- تحضير القطبتأكد من سلامة هيكل الأعمدة وتباعدها بشكل مناسب (عادةً ما تكون المسافة بين الأعمدة 30-50 مترًا). ركّب أدوات مثل الأقواس أو المشابك لدعمها. كابل الألياف الضوئية.

- تحضير الكابلات:اختر هوائيًا كابل الألياف الضوئية مع غلاف مقاوم للعوامل الجوية وعناصر متينة لتحمل الرياح والجليد. افرد الكابل بعناية لتجنب الالتواءات أو التلف.

- ربط الكابل:استخدم آلية سحب، مثل الرافعة، لربط كابل الألياف الضوئية بين القطبين. ثبّت الكابل بالمشابك، مع التأكد من الشد المناسب لمنع الترهل، مع تجنب الشد الزائد الذي قد يُسبب إجهادًا. كابل الألياف الضوئية.

- التوصيل والإنهاء:في النقاط المحددة، قم بتوصيل كابل الألياف الضوئية لتوصيل الأجزاء أو إنهائها عند صندوق التوصيل. استخدم التوصيل الانصهاري لتقليل فقدان الإشارة في تقنية الألياف البصرية.

- الاختبار: اختبر الاتصال باستخدام جهاز OTDR للتحقق من فقدان الإشارة أو وجود أعطال. تأكد من تركيب كابلات الألياف الضوئية يلبي معايير الأداء.

- التأمين والصيانة:تأمين كابل الألياف الضوئية مع الربط المناسب لمنع الحركة، ووضع جدول للتفتيشات المنتظمة لمعالجة التآكل الناتج عن الظروف الجوية.

جوي تركيب كابلات الألياف الضوئية تعتبر فعالة من حيث التكلفة بالنسبة للمناطق الكبيرة ولكنها تتطلب صيانة مستمرة لحماية كابلات الألياف الضوئية من العوامل البيئية.

تركيب كابلات الألياف الضوئية المدفونة مباشرة

دفن مباشر تركيب كابلات الألياف الضوئية يتضمن وضع كابلات الألياف الضوئية مُباشرةً في الأرض دون الحاجة إلى قناة، ويُستخدم غالبًا في الشبكات الريفية البعيدة. إليك العملية:

- تخطيط المسار: امسح مسار التركيب، متجنبًا العوائق كالصخور أو المرافق القائمة. احصل على تصاريح الحفر، وحدد المرافق الموجودة تحت الأرض لمنع حدوث أي ضرر أثناء التركيب. تركيب كابلات الألياف الضوئية.

- حفر الخنادق: احفر خندقًا، بعمق يتراوح عادةً بين ٠٫٦ و١٫٢ متر، حسب اللوائح المحلية وظروف التربة. تأكد من أن الخندق واسع بما يكفي لاستيعاب كابل الألياف الضوئية (حوالي 15-30 سم).

- تحضير الكابلات:اختر دفنًا مباشرًا كابل الألياف الضوئية مع غلاف متين ومقاوم للرطوبة. ضع الكابل بشكل مسطح لتجنب الالتواء أو الانحناء بما يتجاوز الحد الأدنى لنصف قطر الانحناء.

- وضع الكابل: ضع كابل الألياف الضوئية في الخندق، أضف طبقة من الرمل أو الحصى أسفله وفوقه لحمايته من الأجسام الحادة. استخدم شريط تحذير فوق الكابل لتنبيه الحفارات المستقبلية.

- الردماملأ الخندق بالتربة، وضغطها لمنع ترسبها. تجنب الصخور الكبيرة التي قد تُلحق الضرر بالخندق. كابل الألياف الضوئية متأخر , بعد فوات الوقت.

- التوصيل والإنهاء:وصل كابل الألياف الضوئية عند نقاط التوصيل أو إنهائها عند نقاط الوصول مثل فتحات الصرف الصحي، باستخدام إغلاقات الوصلات الواقية للحماية من الرطوبة.

- الاختبار والتوثيق:اختبار تركيب كابلات الألياف الضوئية باستخدام جهاز OTDR للتحقق من سلامة الإشارة. وثّق المسار للرجوع إليه مستقبلًا، مع ملاحظة عمق وموقع كابلات الألياف الضوئية.

دفن مباشر تركيب كابلات الألياف الضوئية إنها متينة ولكنها تتطلب تخطيطًا دقيقًا لحماية كابلات الألياف الضوئية من حركة التربة أو الحفر العرضي.

تركيب كابلات الألياف الضوئية تحت الماء

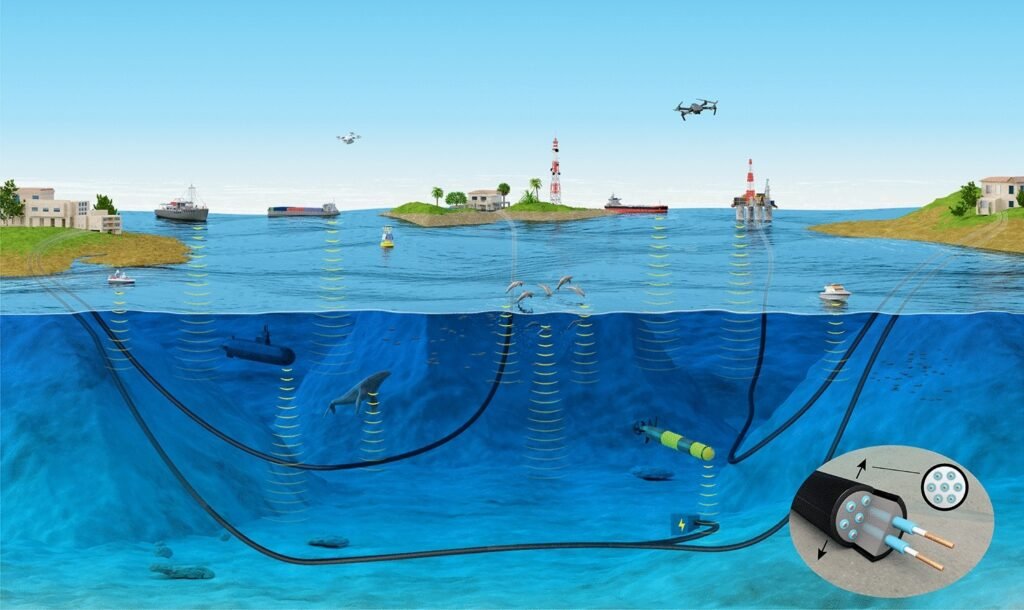

غواصة تركيب كابلات الألياف الضوئية يستخدم لوضع كابلات الألياف الضوئية عبر المحيطات والبحيرات، رابطًا القارات للتواصل العالمي. إليك كيفية القيام بذلك:

- تخطيط المسار: ارسم خريطةً للمسار تحت الماء، متجنبًا المخاطر مثل حطام السفن والبراكين تحت الماء ومناطق الصيد. أجرِ مسوحاتٍ لقاع البحر لتقييم العمق والتضاريس. تركيب كابلات الألياف الضوئية.

- اختيار الكابل:استخدم غواصة كابل الألياف الضوئية مع طبقات حماية متعددة، بما في ذلك درع فولاذي وسترة مقاومة للماء، لتحمل ضغط المياه والتيارات والنشاط البحري.

- تحضير وضع الكابلات:تحميل كابل الألياف الضوئية على متن سفينة متخصصة في وضع الكابلات مزودة بمحراث أو مركبة يتم التحكم فيها عن بعد (ROV) لتوجيه الكابل إلى قاع البحر.

- وضع الكابل:اخفض كابل الألياف الضوئية إلى قاع البحر، باستخدام المحراث لدفنه في المياه الضحلة (حتى عمق 1000 متر) لحمايته من المراسي أو معدات الصيد. في المياه العميقة، قد يستقر الكابل على قاع المحيط.

- التوصيل والتوصيل:عند نقاط الهبوط على الشاطئ، قم بربط الغواصة كابل الألياف الضوئية إلى الكابلات الأرضية، باستخدام صناديق الوصل المقاومة للماء لمنع التآكل في تقنية الألياف البصرية.

- الاختبار:اختبار كامل تركيب كابلات الألياف الضوئية لضمان استمرارية الإشارة وفقدانها، مما يضمن أداء الكابل لمسافات طويلة عبر المحيط.

- المراقبة والصيانة:نشر أجهزة استشعار لمراقبة كابل الألياف الضوئية للأضرار الناجمة عن الأحداث الطبيعية كالزلازل. استخدم سفن الإصلاح لإصلاح الأعطال، وقد يتطلب ذلك استعادة وتوصيل كابلات الألياف الضوئية.

غواصة تركيب كابلات الألياف الضوئية إن تكنولوجيا المعلومات والاتصالات معقدة ومكلفة ولكنها ضرورية للاتصال العالمي بالإنترنت، وتتطلب معدات وخبرات متخصصة.

تركيب كابلات الألياف الضوئية الداخلية

داخلي تركيب كابلات الألياف الضوئية يُستخدم داخل المباني، مثل المكاتب أو مراكز البيانات، لتوصيل الأجهزة أو الغرف. إليك العملية خطوة بخطوة:

- تخطيط الطريق: ارسم خريطة لمسار الكابلات داخل المبنى، باستخدام صواني الكابلات أو الأنابيب أو مساحات السقف الموجودة. تأكد من الامتثال لقوانين السلامة من الحرائق. تركيب كابلات الألياف الضوئية.

- اختيار الكابل:اختر مكانًا داخليًا كابل الألياف الضوئية مع غلاف مقاوم للهب، مثل الكابل المخصص للمساحات المخصصة للتعامل مع الهواء، لتلبية معايير السلامة في تقنية الألياف البصرية.

- توجيه الكابلات: قم بتشغيل كابل الألياف الضوئية عبر الأنابيب أو الصواني، مع تجنب الانحناءات الحادة التي تتجاوز الحد الأدنى لنصف قطر انحناء الكابل (عادةً عشرة أضعاف قطر الكابل). ثبّت الكابل برباطات أو مشابك.

- التوصيل والإنهاء:إنهاء كابل الألياف الضوئية في لوحات التوصيل أو رفوف المعدات، باستخدام موصلات مثل SC أو LC. وصل الكابلات عند الحاجة، مما يضمن أقل قدر من فقدان الإشارة.

- الاختبار:استخدم جهاز OTDR أو مصدر الضوء ومقياس الطاقة لاختبار تركيب كابلات الألياف الضوئية، التحقق من فقدان الإشارة أو وجود أخطاء في الاتصال.

- وضع العلامات والتوثيق: قم بتسمية كابل الألياف الضوئية على كلا الطرفين لسهولة التعرف عليها، وتوثيق مخطط التثبيت للصيانة المستقبلية.

- التعديلات النهائية:فحص الإعداد للتأكد من كابلات الألياف الضوئية يتم تثبيتها بشكل آمن وحمايتها من التلف المادي داخل البيئة الداخلية.

داخلي تركيب كابلات الألياف الضوئية يعطي الأولوية للسلامة وإمكانية الوصول، مما يضمن كابلات الألياف الضوئية دعم الشبكات عالية السرعة داخل المبنى.

تركيب كابلات الألياف الضوئية الخارجية

في الهواء الطلق تركيب كابلات الألياف الضوئية يربط المباني أو المرافق على مساحات أكبر، غالبًا في المناطق الحضرية أو الضواحي، باستخدام طرق مثل القنوات. إليك العملية:

- تخطيط المسار:خطط للمسار الخارجي، وحدد القنوات الموجودة أو خطط لقنوات جديدة. تحقق من العوامل البيئية مثل حركة المرور أو الطقس التي قد تؤثر على تركيب كابلات الألياف الضوئية.

- تحضير القناة:قم بتثبيت أو استخدام القنوات الموجودة تحت الأرض، المصنوعة عادةً من مادة PVC أو HDPE، لحماية كابل الألياف الضوئيةتأكد من أن القنوات نظيفة وخالية من الحطام.

- اختيار الكابل:اختر مكانًا خارجيًا كابل الألياف الضوئية مع سترة مقاومة للأشعة فوق البنفسجية ومقاومة للماء لتحمل الظروف الجوية، مثل تغيرات درجات الحرارة أو المطر، تقنية الألياف البصرية.

- سحب الكابل أو نفخه:استخدم حبل السحب أو تقنية نفخ الهواء لتغذية كابل الألياف الضوئية من خلال القناة، مع التأكد من عدم تمدد الكابل أو ثنيه بشكل مفرط.

- التوصيل والإنهاء:وصل كابل الألياف الضوئية في فتحات الصرف الصحي أو صناديق الوصلات، وإنهائها في الخزانات أو المباني الخارجية، باستخدام حاويات مقاومة للعوامل الجوية.

- الاختبار:اختبار تركيب كابلات الألياف الضوئية باستخدام جهاز OTDR للتحقق من جودة الإشارة، ومعالجة أي مشكلات مثل فقدان الإشارة أو تلفها.

- الختم والحماية:قم بإغلاق مداخل القنوات ونقاط الوصل لمنع دخول المياه، واستخدم مواد مقاومة للقوارض لحماية كابلات الألياف الضوئية من الأضرار البيئية.

في الهواء الطلق تركيب كابلات الألياف الضوئية يضمن المتانة في الظروف القاسية، مما يوفر اتصالاً موثوقًا به عبر مناطق أكبر.

فوائد تركيب كابلات الألياف الضوئية بشكل صحيح

اتصال عالي السرعة وموثوق به

سليم تركيب كابلات الألياف الضوئية يضمن اتصالاً موثوقًا وعالي السرعة عبر جميع الطرق. في تقنية الألياف البصرية، تم تثبيته بشكل صحيح كابلات الألياف الضوئية تقليل فقدان الإشارة، وتوفير أداء ثابت للتطبيقات مثل الوصول إلى الإنترنت، وبث الفيديو، ونقل البيانات، سواء من خلال التركيبات الجوية، أو المدفونة مباشرة، أو تحت الماء، أو الداخلية، أو الخارجية.

متانة طويلة الأمد وصيانة منخفضة

تم تنفيذه بشكل جيد تركيب كابلات الألياف الضوئية يعزز متانة كابلات الألياف الضوئيةمما يقلل الحاجة إلى الصيانة المتكررة. على سبيل المثال، غواصة مدفونة بشكل صحيح كابل الألياف الضوئية يمكن أن تدوم لعقود من الزمن مع الحد الأدنى من الإصلاحات، في حين أن الكابل الداخلي المثبت مع وضع السلامة من الحرائق في الاعتبار يتجنب عمليات الاستبدال المكلفة، مما يضمن الموثوقية على المدى الطويل في تقنية الألياف البصرية.

قابلية التوسع لتلبية الاحتياجات المستقبلية

سليم تركيب كابلات الألياف الضوئية يسمح بالتوسع، مما يتيح للشبكات التعامل مع المتطلبات المستقبلية. في تقنية الألياف البصرية، تركيب سعة إضافية (على سبيل المثال، الألياف الداكنة) أثناء تركيب كابلات الألياف الضوئية يضمن أن الشبكة قادرة على دعم حركة البيانات المتزايدة، مما يجعلها حلاً مستقبليًا لتلبية احتياجات الاتصال المتزايدة عبر جميع طرق التثبيت.

التحديات في تركيب كابلات الألياف الضوئية

التحديات البيئية والتضاريسية

كل تركيب كابلات الألياف الضوئية تواجه هذه الطريقة تحديات بيئية فريدة. كابلات الألياف الضوئية تتعرض الكابلات المدفونة مباشرة للرياح والجليد، وتواجه تغيرات التربة، وتتعامل الكابلات البحرية مع ضغط المياه، ويجب أن تتحمل الكابلات الخارجية الظروف الجوية القاسية. تقنية الألياف البصريةوالتخطيط الدقيق وتصميم الكابلات القوي ضروريان للتغلب على هذه التحديات أثناء تركيب كابلات الألياف الضوئية.

تكاليف أولية عالية وخبرة

تركيب كابلات الألياف الضوئية قد يكون مكلفًا ويتطلب خبرة متخصصة. الغواصة تركيب كابلات الألياف الضوئيةعلى سبيل المثال، تتضمن سفنًا ومعدات باهظة الثمن، بينما تتطلب التركيبات الداخلية معرفة قواعد مكافحة الحرائق. تقنية الألياف البصرية، فإن الحاجة إلى الفنيين المهرة والأدوات المتقدمة يمكن أن تجعل تركيب كابلات الألياف الضوئية يعد هذا استثمارًا كبيرًا، على الرغم من أن الفوائد طويلة الأجل غالبًا ما تفوق التكاليف.

خطر التلف أثناء التثبيت

خطر التلف كابلات الألياف الضوئية خلال تركيب كابلات الألياف الضوئية هو تحدي شائع. في تقنية الألياف البصرية، الانحناء المفرط، أو الوصل غير السليم، أو التعرض للرطوبة يمكن أن يضعف كابل الألياف الضوئيةأداء. تتطلب كل طريقة - سواء كانت جوية، أو مدفونة مباشرة، أو تحت الماء، أو داخلية، أو خارجية - معالجة دقيقة لمنع التلف، وضمان نجاح العملية. تركيب كابلات الألياف الضوئية.

الاستنتاج: إتقان تركيب كابلات الألياف الضوئية

تركيب كابلات الألياف الضوئية هي عملية بالغة الأهمية تعمل على تمكين عالمنا المتصل، وتمكين الاتصالات عالية السرعة والموثوقة من خلال تقنية الألياف البصريةسواء كان جويًا كابلات الألياف الضوئية معلقة على أعمدة، أو كابلات مدفونة مباشرة تحت الأرض، أو كابلات بحرية تعبر المحيطات، أو كابلات داخلية وخارجية تربط المباني، كل منها تركيب كابلات الألياف الضوئية تتطلب هذه الطريقة نهجًا مُصممًا خصيصًا لضمان النجاح. باتباع الإرشادات التفصيلية الموضحة أعلاه، يمكن للفنيين إنشاء شبكات موثوقة ومتينة وقابلة للتطوير تلبي المتطلبات الحديثة. على الرغم من وجود تحديات مثل العوامل البيئية والتكاليف ومخاطر التلف، إلا أن فوائد الصيانة المناسبة تركيب كابلات الألياف الضوئية—مثل الاتصال عالي السرعة والموثوقية طويلة الأمد— تجعله استثمارًا جديرًا بالاهتمام. تقنية الألياف البصرية يستمر في التطور وإتقان تركيب كابلات الألياف الضوئية ستظل عنصرا أساسيا في بناء شبكات المستقبل، وضمان ذلك كابلات الألياف الضوئية أبقِنا على اتصال، بغض النظر عن البيئة.