As of August 06, 2025, the global demand for fiber optic networks continues to soar, driven by 5G expansion, smart city initiatives, and cloud computing. Fiber optic cables, the backbone of these networks, vary significantly based on their intended environment—outdoor or indoor. This guide offers a technical comparison of outdoor and indoor fiber optic cables, exploring their construction, performance metrics, applications, and installation challenges. Designed for professionals sourcing solutions from CommMesh, it provides actionable insights to optimize network deployments in 2025’s dynamic landscape.

Introduction to Outdoor and Indoor Fiber Optic Cables

Fiber optic cables transmit data as light pulses through a glass or plastic core, offering bandwidths up to 400 Gbps per fiber via wavelength-division multiplexing (WDM). However, their design differs markedly depending on whether they are deployed outdoors—exposed to weather, soil, and physical stress—or indoors, where controlled conditions prevail. Outdoor cables are engineered for durability against environmental hazards, while indoor cables prioritize flexibility and ease of termination. As of August 2025, with over 1.6 million km of fiber deployed globally (per TeleGeography), understanding these differences is critical for efficient network planning.

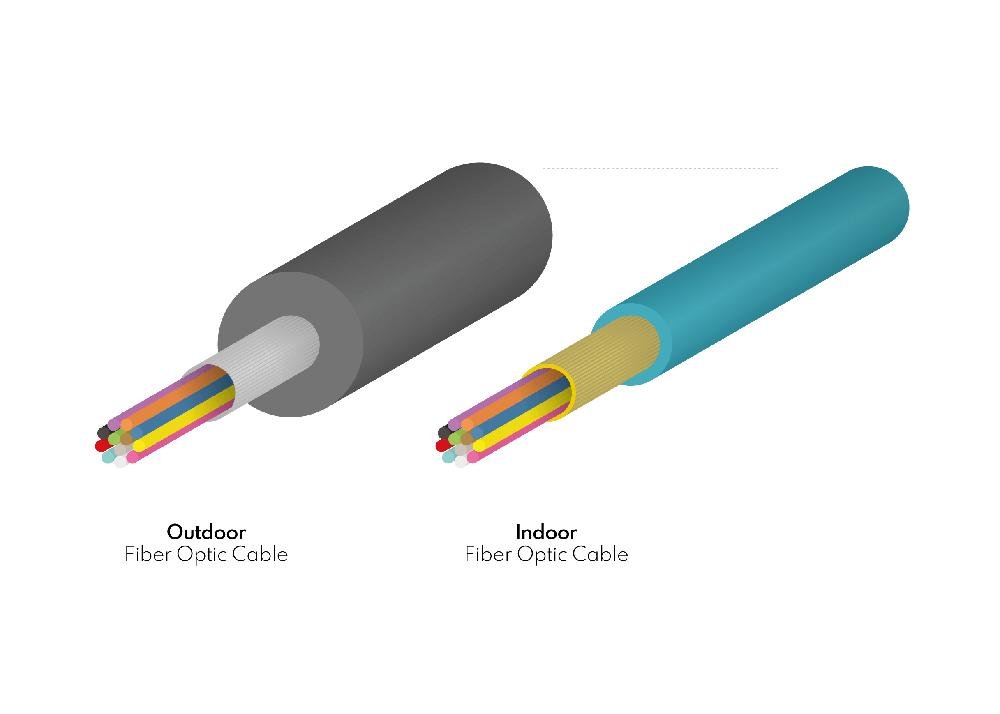

Comparison of Outdoor Fiber Optic Cable and Indoor Fiber Optic Cable Structures

The construction of fiber optic cables reflects their environmental demands:

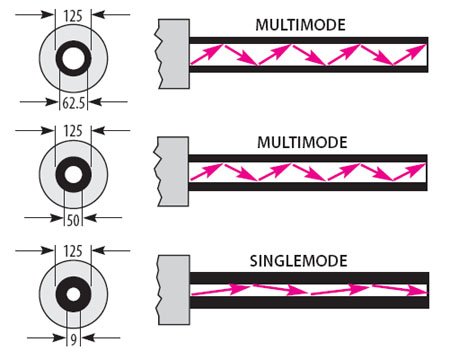

- Optical Fiber (Core and Cladding)

- Both types feature a core (8–62.5 μm) and cladding (125 μm), made of silica with a refractive index of 1.46 (core) and 1.44 (cladding) to enable total internal reflection.

- Outdoor: Single-mode (8–10 μm) dominates for long-haul (100 km, 0.2 dB/km loss).

- Indoor: Multimode (50–62.5 μm) is common for short runs (2 km, 1–3 dB/km loss).

- Technical Note: Core purity (99.9999% silica) minimizes scattering in both.

- Buffer Coating

- Outdoor: A 250–900 μm thick acrylate or silicone buffer resists moisture and temperature swings (-40°C to 70°C), with tensile strength of 600–1000 N.

- Indoor: A 900 μm tight buffer enhances flexibility for indoor bends (10 mm radius), with 500–800 N strength.

- Difference: Outdoor buffers are thicker to combat environmental stress, while indoor buffers prioritize termination ease.

- Strength Members

- Outdoor: Aramid yarn or fiberglass rods (1000–3000 N) handle tensile loads during burial or aerial installation (e.g., 50 kN/m² soil pressure).

- Indoor: Lighter aramid yarn (500–1000 N) supports indoor pulls, reducing weight for ceiling or wall runs.

- Difference: Outdoor members are robust for 1.0–1.5 m burial depths, while indoor members suit 0.1–0.3 m conduit runs.

- Jacket

- Outdoor: Polyethylene or armored steel tape jackets (5–10 mm) offer UV resistance, water ingress protection (IP68, 0.1 MPa), and 1000 N extra strength.

- Indoor: PVC or LSZH jackets (2–5 mm) reduce smoke and toxicity in fires, with 500 N strength and 0.05 MPa water resistance.

- Difference: Outdoor jackets withstand -40°C to 70°C, while indoor jackets focus on fire safety (90% less smoke).

- Additional Features

- Outdoor: Water-blocking gel or tapes prevent 0.01% moisture ingress, critical for underground or aerial use.

- Indoor: No gel, as indoor environments lack moisture risks, enhancing flexibility.

- Difference: Outdoor cables add 10–20% weight for protection.

| Component | Outdoor | Indoor | Key Difference |

|---|---|---|---|

| Core Type | Single-Mode (8–10 μm) | Multimode (50–62.5 μm) | Distance vs. cost |

| Buffer Thickness | 250–900 μm | 900 μm | Durability vs. flexibility |

| Strength Members | 1000–3000 N | 500–1000 N | Load capacity |

| Jacket Material | PE, Armored | PVC, LSZH | Environmental vs. safety |

| Additional Protection | Water-blocking gel | None | Moisture resistance |

Performance Comparison Between Outdoor Fiber Optic Cable and Indoor Fiber Optic Cable

Performance metrics highlight their distinct purposes:

- Attenuation and Distance

- Outdoor: 0.2–0.4 dB/km for single-mode, supporting 100 km without repeaters, ideal for rural broadband.

- Indoor: 1–3 dB/km for multimode, limited to 2 km, suited for LANs.

- Difference: Outdoor cables prioritize long-haul efficiency, while indoor cables optimize short-range cost.

- Bandwidth

- Outdoor: Up to 400 Gbps per fiber with WDM, supporting 128 channels at 1310/1550 nm.

- Indoor: 10–100 Gbps, sufficient for 100-meter data center links.

- Difference: Outdoor bandwidth scales for backbone networks, while indoor meets local needs.

- Environmental Tolerance

- Outdoor: -40°C to 70°C, 1000 N/cm crush resistance, and 0.1 MPa water pressure tolerance.

- Indoor: 0°C to 60°C, 500 N/cm crush resistance, and minimal water exposure.

- Difference: Outdoor cables endure harsher conditions, indoor cables focus on stability.

- Durability

- Outdoor: 20–30 year lifespan with proper burial (0.9–1.5 m), resisting 50 kN/m² soil pressure.

- Indoor: 10–20 years in controlled settings, with 0.1–0.3 m conduit runs.

- Difference: Outdoor longevity suits infrastructure, indoor suits temporary setups.

Applications Comparison Between Outdoor Fiber Optic Cable and Indoor Fiber Optic Cable

The applications of outdoor and indoor fiber optic cables reflect their design strengths as of August 2025:

- Outdoor Fiber Optic Cables

- Long-Haul Networks: Single-mode cables support 100 km runs with 0.2 dB/km loss, ideal for transcontinental links. Example: A 2025 China Unicom project deployed 5000 km of loose-tube cables for rural 5G backhaul.

- Aerial and Buried Installations: Armored cables withstand 1000 N/cm crush loads, used in power line co-deployment and 1.0–1.5 m burials.

- Harsh Environments: Water-blocking gel protects against 0.1 MPa pressure in flood-prone areas, supporting 30% of global fiber growth (per CRU Group).

- Technical Note: Tensile strength of 3000 N handles aerial spans up to 200 m.

- Indoor Fiber Optic Cables

- Data Centers: Multimode cables (50 μm) deliver 100 Gbps over 100 meters, with 144-core ribbon designs saving 40% duct space. Google’s 2025 Singapore facility uses 96-core indoor cables.

- Building Backbones: Tight-buffered cables connect floors, supporting 10 Gbps LANs with 0.3 m conduit runs.

- FTTH Drops: Flexible designs simplify home installations, reducing labor by 50% (per FTTH Council 2025 data).

- Technical Note: 500 N strength suits 10 mm bend radii in tight spaces.

Installation Considerations Comparison

Installation practices differ based on environment:

- Outdoor Fiber Optic Cables

- Burial Depth: 0.9–1.5 meters, below frost lines (e.g., 1.2 m in northern regions), resisting 50 kN/m² soil pressure.

- Trenching and Splicing: Requires heavy machinery and fusion splicing (0.01–0.05 dB loss), taking 10 minutes per joint.

- Environmental Prep: Water-blocking gel and armored jackets protect against -40°C to 70°C and 0.1 MPa water pressure.

- Technical Note: OTDR testing at 1310/1550 nm ensures <0.2 dB/km loss post-installation.

- Indoor Fiber Optic Cables

- Conduit Runs: 0.1–0.3 meters in walls or ceilings, with 10–20 mm bend radii to avoid 0.01% loss.

- Termination: Plug-and-play or mechanical splicing (0.1–0.3 dB loss) takes 5 minutes, using LC/SC connectors.

- Environmental Prep: No gel needed; LSZH jackets reduce smoke by 90% in fire scenarios.

- Technical Note: Power meters verify <1 dB/km loss in controlled settings.

Cost Analysis Comparison

Cost varies with construction and deployment:

- Outdoor Fiber Optic Cables

- Material Cost: $0.50–$2.00/meter, with armored variants at $1.50–$3.00/meter due to steel tape and gel.

- Installation Cost: $500–$1000/km, including trenching and splicing labor.

- Lifespan Cost: 20–30 years, with 10% maintenance (e.g., $50/km/year).

- Example: A 2025 rural project in India spent $2 million for 2000 km.

- Indoor Fiber Optic Cables

- Material Cost: $0.30–$1.00/meter, as LSZH and tight buffering are cheaper.

- Installation Cost: $200–$500/km, with simpler conduit runs and terminations.

- Lifespan Cost: 10–20 years, with 5% maintenance (e.g., $20/km/year).

- Example: A 2025 office build in Tokyo cost $100,000 for 200 km.

| Aspect | Outdoor | Indoor | Difference |

|---|---|---|---|

| Material Cost | $0.50–$3.00/meter | $0.30–$1.00/meter | 50–200% higher outdoor |

| Installation Cost | $500–$1000/km | $200–$500/km | 150% higher outdoor |

| Lifespan Cost | 20–30 years, 10% maint. | 10–20 years, 5% maint. | Longer outdoor durability |

Challenges Comparison

Each type faces unique hurdles:

- Outdoor Fiber Optic Cables

- Environmental Stress: -40°C to 70°C and 0.1 MPa water pressure can degrade jackets, causing 5% failure over 20 years. Solution: Armored designs and gel.

- Installation Complexity: Trenching at 1.5 m depth increases labor by 30%. Solution: Micro-trenching reduces costs by 20%.

- Cost: Higher upfront investment ($2 million/2000 km). Solution: Bulk orders save 15%.

- Indoor Fiber Optic Cables

- Fire Risk: PVC jackets emit toxic smoke in fires. Solution: LSZH reduces toxicity by 90%.

- Space Constraints: 10 mm bends risk 0.01% loss in tight ducts. Solution: Flexible buffers mitigate this.

- Durability: 10–20 year lifespan limits long-term use. Solution: Upgrades planned every 10 years.

Future Trends Comparison

Innovations as of August 2025 shape both types:

- Outdoor Fiber Optic Cables

- Higher Core Counts: 288-core cables with 115 Tbps capacity are in testing, targeting 2026 rural deployments.

- Sustainability: Bio-based jackets cut carbon by 10%, aligning with 2025 EU goals.

- Automation: Robotic trenching systems aim for 50 m/hour, reducing labor by 30%.

- Indoor Fiber Optic Cables

- Smart Fibers: IoT sensors monitor 0.01 dB loss in real-time, enhancing data center efficiency by 15%.

- Miniaturization: 1 mm diameter cables for 5G in-building use are in development, saving 50% space.

- Fire Safety: Halogen-free materials reduce smoke by 95%, per 2025 safety codes.

Conclusion

Outdoor and indoor fiber optic cables serve distinct roles in 2025’s network ecosystem. Outdoor cables, with their robust construction (e.g., armored jackets, water-blocking gel), excel in long-haul and harsh environments, supporting 100 km runs with 0.2 dB/km loss. Indoor cables, with flexible tight buffers and LSZH jackets, optimize short-range, fire-safe applications like data centers and FTTH. Their cost, installation, and performance differences guide deployment choices, while future trends like higher core counts and smart sensors promise enhanced capacity and efficiency. For tailored solutions, explore CommMesh.