- +1 (510) 365-3338

- +1 5103653338

- evan@commmesh.com

- +86 15274842581

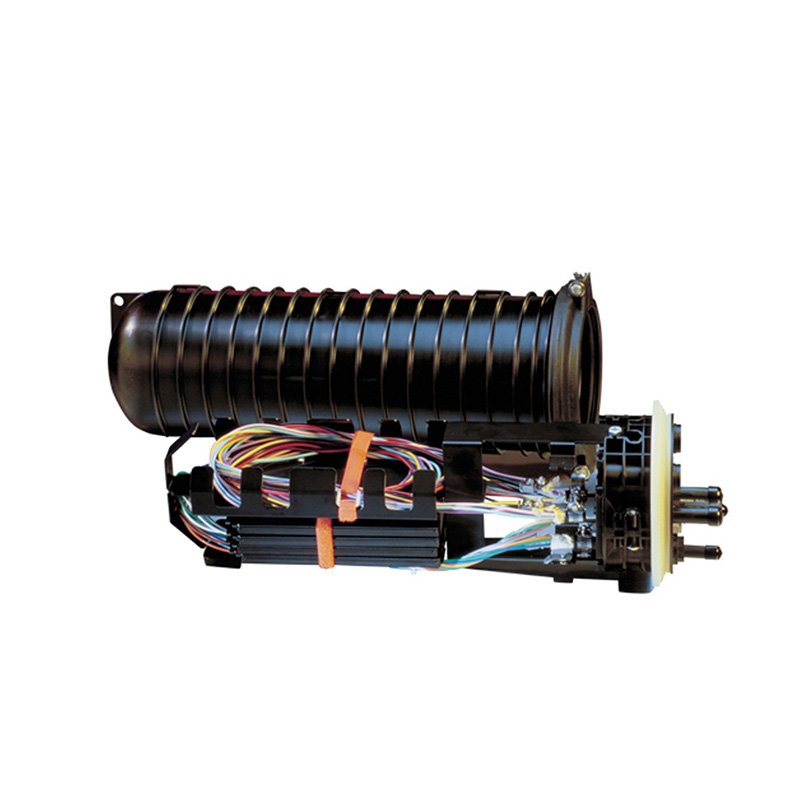

A splice closure fiber keeps your internet working well. It is a strong box, protecting fiber optic connections. Imagine tiny glass wires inside cables. These cables link when using a special splice tray. The closure body, often made from HDPE, is super tough.

It protects from rain, with an IP68 rating. The O-ring seal stops water. Thus, signals travel fast, at 1550 nm. You can find different sizes, like 300 mm long ones. It can also include up to 24 fibers inside. Some have 2 main ports. Strain relief keeps cables safe from pulling.

Also, the closure uses mechanical grommets or heat shrink tubing for sealing. The dome shape adds strength. Think of it as a tough shell. GR-771-CORE is a standard it follows. TIA/EIA-568 is another important standard. A grounding stud protects from electrical issues.

The gel seal features prevent water ingress. Cold-Shrink Tubing is essential for simple installation. Finally, the splice closure fiber keeps everything secure.

A splice closure fiber firmly holds fiber connections together. You use it for fusion splicing, creating a strong link. This link can have a loss as low as 0.01 dB.

Furthermore, mechanical splicing offers another joining option. These joints resist up to 20 joules of force, based on the IK10 rating. Because the splice holders keep things stable. This prevents bending and stress.

This device protects fibers from many threats. It resists harmful UV radiation effectively. It is also designed to withstand temperature fluctuations. Besides, the structure works from -40 °C to +65 °C. The material is polypropylene, resisting many chemicals.

The shell shields against road salt. Consequently, the closure remains safe for aerial mounting. It protects from dust thanks to its design.

You can re-enter this protective device easily. The splice closure fiber uses a simple latch system. The design includes metal clamps made of stainless steel. In fact, the splice trays often are hinged. This means you can get to each splice quickly. Accessing fibers is easy, owing to clever interior design. Fiber routing is simple inside.

This enclosure manages cables neatly inside, you see. The internal fiber management includes spaces for extra cable. Slack storage helps with future fixes. The routing guides and channels keep everything orderly. In particular, the bend radius control is very vital. Fibers must bend, greater than 30 mm, generally. The closure also includes 4 smaller ports and clips.

The splice closure fiber will serve reliably for many years. Moreover, REACH Compliance ensures safety regarding chemical use. The device meets RoHS Compliance standards, as well. Its materials resist breaking down. Overall dimensions could be 400 mm length.

Consequently, it can last, even buried underground. The sturdy ABS plastic in trays add durability. This guarantees long-term performance.

| Specification | Material | Max. Capacity | Temp. Range (°C) | Cable Ports | Sealing Type | Mounting Type | Standard | Typical Loss (dB) |

| Small Capacity | PP | 24 fibers | -40 to +65 | 2 + 2 | Heat Shrink | Aerial, Wall | GR-771-CORE | 0.01 |

| Medium Capacity | HDPE | 96 fibers | -40 to +70 | 4 + 4 | Gel Seal | Aerial, Pole | TIA/EIA-568 | 0.02 |

| Large Capacity | ABS | 288 fibers | -40 to +80 | 6 + 8 | Mechanical | Underground | IEC 61753 | 0.05 |

| Aerial Closure | UV-Resistant PP | 48 fibers | -30 to +60 | 2 + 4 | Grommet | Aerial Strand | GR-771-CORE | 0.03 |

| Direct Burial | HDPE | 144 fibers | -40 to +75 | 4 + 2 | Cold Shrink | Direct Burial | TIA/EIA-568 | 0.04 |

| High Density | PC/ABS Blend | 432 fibers | -45 to +85 | 8 + 16 | Gel, Compression | Vault, Pedestal | IEC 61753 | 0.02 |

| Compact Closure | PP | 12 fibers | -20 to +60 | 1+1 | Rubber | Wall | GR-771-CORE | 0.1 |

| Branch Closure | Thermoplastic | 72 fibers | -40 to +65 | 6 total | Heat Shrink | Pole | REACH | 0.03 |

| Low-Loss Closure | Polycarbonate | 144 fibers | -35 to 70 | 4 total | O-Ring | Aerial | RoHS | 0.01 |

The splice closure fiber guarantees a complete waterproof barrier. Its EPDM rubber O-ring creates a tight seal. This crucial seal provides ingress protection, defending connections. Therefore, it meets the standard. You can expect protection, even under 1 meter of water. Besides, the closure mechanism maintains constant pressure. The diameter of the sealing area might be 200 mm.

This device boasts an incredibly robust outer layer. The high-density polyethylene construction provides excellent impact resistance. It therefore can resist damage. The closure body withstands various external pressures. The dome shape adds inherent structural integrity. Furthermore, the shell can even be direct burial rated. The typical wall thickness could be around 5 mm. This robust shell protects the fibers.

The design of this splice closure fiber prioritizes simple re-entry. The clamping system, is not complex. Quick access is available for any needed maintenance. The release is also smooth. You do not need special tools generally. Because, removable components simplify repeated use. Furthermore, there are no difficult locks. The closure has a very efficient locking mechanism. Accessing the IEC 61753 is very simple.

Inside the splice closure fiber, neatness creates better signal quality. Clear fiber optic cable paths prevent any signal loss. The minimum bend radius, about 10 times the fiber diameter, is carefully maintained. Internal clamps hold cables securely in their place. The tie-down points add additional security for cables, as a result. Each tray can typically accommodate 12 splices.

Quick Contact

To save your time, please contact us quickly via the form below to get an instant quote.