In the precision-driven world of fiber optic networking, where signal integrity, latency, and density are paramount, the adapta ya fiber optic is one of the most critical yet frequently underestimated components. These small passive devices are the mechanical bridges that align and connect two fiber optic connectors, ensuring light signals transfer with minimal loss and reflection.

Also known as fiber adapter, optical fiber adapter, fiber coupler, fiber optic coupler, mating sleeve, or simply adapter, this component is ubiquitous in every fiber network — from FTTH drop terminations to hyperscale data center interconnects and 800G/1.6T Ethernet deployments.

This exhaustive guide covers every aspect of fiber optic adapters in 2026: their fundamental definition and purpose, historical evolution, detailed construction and materials, comprehensive classification of all major types, key performance specifications and industry standards, real-world applications across industries, installation best practices and handling tips, compatibility and hybrid adapter solutions, cost analysis and pricing trends, common pitfalls and troubleshooting techniques, quality control and testing requirements, real-world case studies, and emerging innovations through 2030.

1. What Is a Fiber Optic Adapter? Definition, Purpose, and Fundamental Role

A adapta ya fiber optic is a passive mechanical device that precisely aligns and joins two fiber optic connectors (male-to-male), allowing optical signals to pass from one fiber to another with minimal insertion loss and back-reflection.

Unlike active components (transceivers, amplifiers, repeaters), adapters contain no electronics — they are purely mechanical alignment tools.

1.1 Core Functions in Detail

- Ferrule Alignment: Centers the two ceramic ferrules (2.5 mm for SC/FC/ST, 1.25 mm for LC/MU) so fiber cores align within 0.5–1 micron.

- Physical Contact: Ensures direct contact (PC/UPC) or angled contact (APC) between fiber endfaces to eliminate air gaps and minimize Fresnel reflection.

- Mechanical Stability: Provides secure mating under vibration, temperature changes, and pull forces (≥100 N typical), preventing intermittent connections.

- Connector Type Conversion: Enables hybrid adapters (e.g., SC to LC) for legacy-to-modern transitions without replacing entire cable runs.

- Density Enablement: Allows high-density mounting in fiber patch panels, cassettes, wall boxes, and ODFs, supporting 576+ ports per 1U rack.

- Safety and Protection: Shuttered adapters automatically close when unmated, reducing eye exposure to laser light and protecting against dust.

Without reliable adapters, even the best fiber cable and transceivers would suffer from high insertion loss, excessive reflections, and intermittent failures.

1.2 Why Adapters Are Critical in 2026

- Density Explosion: Data centers now pack 576+ LC ports per 1U rack, with quad LC adapters pushing 1152 ports.

- High-Speed Requirements: 800G/1.6T coherent optics demand ≤0.10 dB insertion loss and ≥65 dB return loss.

- PON & FTTH: APC adapters are mandatory to prevent reflection-induced errors in OLT receivers, especially at 50G/100G rates.

- Legacy Migration: Hybrid adapters bridge old SC/FC systems with modern LC/MPO kupelekwa.

- Safety & Reliability: Shuttered adapters reduce eye exposure to laser light and protect against dust contamination.

A single poor-quality adapter can cause 0.5–1 dB loss, turning a 100 km link into an unreliable one and costing operators millions in troubleshooting and downtime.

1.3 Historical Evolution of Fiber Optic Adapters

- 1980s: Early metal sleeves for FC/ST connectors; manual alignment with limited precision.

- 1990s: Plastic adapters for SC and LC emergence; ceramic sleeves introduced for better alignment.

- 2000s: High-precision zirconia for 10G+ speeds; APC polish for PON and analog video.

- 2010s: Hybrid adapters for 40G/100G; shuttered designs for safety and dust protection.

- 2020s: MPO/MTP adapters for parallel optics; VSFF (Very Small Form Factor) like SN/MDC for 1.6T+.

- 2026+: Smart adapters with RFID and integrated monitoring.

2. Detailed Construction and Materials of Fiber Optic Adapters

2.1 Core Components and Their Functions

- Alignment Sleeve: Zirconia ceramic (premium, ±0.001 mm tolerance) or phosphor bronze (budget, ±0.005 mm). The sleeve is the heart of the adapter, centering the ferrules.

- Housing/Body: Zinc alloy, stainless steel, or high-grade plastic (UL94 V-0 rated) with mounting flanges for panel installation.

- Split Sleeve: Spring-loaded mechanism that holds connectors securely under constant pressure.

- Dust Cap/Shutter: Metal or plastic cap; shuttered versions automatically close when unmated for laser safety and dust protection.

- Keying/Notch: Ensures correct orientation (especially for APC to prevent UPC mating).

2.2 Ferrule Alignment Tolerance

- Ceramic Sleeve: Tolerance ±0.001 mm → lowest insertion loss and best repeatability.

- Bronze Sleeve: Tolerance ±0.005 mm → acceptable for multimode, higher IL in single-mode.

Premium adapters use zirconia sleeves for both SM and MM.

2.3 Housing Variations

- Rahisix: Single connector mating.

- Duplex: Two connectors (most common for SC/LC).

- Quad: Four Viunganishi vya LC for ultra-density.

- Panel-Mount: Flanged for rack mounting.

- Bulkhead: For wall or box penetration.

- Hybrid: SC to LC, LC to FC, LC to MPO, etc.

2.4 Polish Compatibility

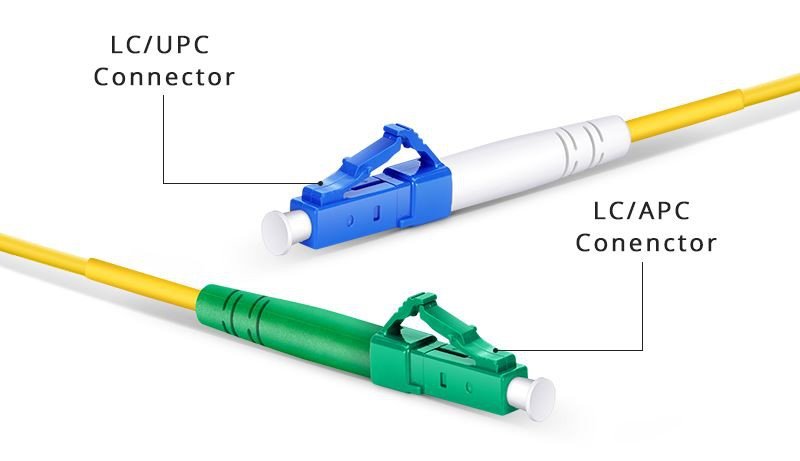

- UPC (Ultra Physical Contact): Flat polish, blue housing, ≥50–55 dB return loss.

- APC (Angled Physical Contact): 8° angle, green housing, ≥60–70 dB return loss.

- Kompyuta (Physical Contact): For multimode, ≥30 dB return loss.

Mixing UPC/APC causes severe reflection (–35 to –45 dB).

2.5 Materials and Manufacturing Quality

- Premium: Zirconia ceramic sleeve, stainless steel housing.

- Standard: Ceramic sleeve, zinc alloy housing.

- Budget: Bronze sleeve, plastic housing.

CommMesh uses zirconia sleeves in all adapters for consistent ≤0.08 dB insertion loss.

3. Comprehensive Classification of Fiber Optic Adapter Types

3.1 By Connector Type (Most Common)

| Aina ya Adapta | Ukubwa wa Ferrule | Housing Color | Typical Applications | 2025 Market Share |

|---|---|---|---|---|

| Adapta ya SC | 2.5 mm | Blue (UPC) / Green (APC) | FTTH, telecom, CATV | 45% |

| Adapta ya LC | 1.25 mm | Blue / Green | Data centers, high-density panels | 40% |

| Adapta ya FC | 2.5 mm | Silver | Test equipment, precision applications | 6% |

| Adapta ya ST | 2.5 mm | Black | Legacy enterprise, industrial | 3% |

| Adapta ya MU | 1.25 mm | Bluu | High-density telecom | 2% |

| MPO/MTP Adapter | Multi-fiber | Black | 40G–1.6T parallel optics | 4% (growing) |

| E2000 Adapter | 2.5 mm | Kijani | Europe, secure environments | 1% |

SC and LC dominate >85% of the market in 2026.

3.2 By Fiber Mode

- Single-Mode Adapters: Tighter tolerances (0.125 mm sleeve) for OS2 fibers.

- Multimode Adapters: Larger alignment for OM3/OM4/OM5.

3.3 By Polish Type

- UPC (Ultra Physical Contact): Flat, ≥50–55 dB return loss.

- APC (Angled Physical Contact): 8° angle, ≥60–70 dB return loss.

- Kompyuta (Physical Contact): For multimode, ≥30 dB return loss.

3.4 By Configuration

- Simplex: Single connection.

- Duplex: Two connectors (most common for SC/LC).

- Quad: Four LC connectors.

- Hybrid: SC to LC, LC to FC, LC to MPO, etc.

3.5 By Mounting Style

- Panel-Mount: Flanged for rack panels.

- Bulkhead: For wall or box penetration.

- Coupler: Free-standing mating sleeve.

3.6 Special-Purpose Adapters

- Shuttered Adapters: Automatic shutter for laser safety.

- Hybrid Adapters: For legacy-to-new transitions.

- Attenuated Adapters: Built-in fixed attenuation (1–20 dB).

- Switchable Adapters: Manual polarity swap.

4. Performance Specifications and Industry Standards

4.1 Optical Performance

- Insertion Loss: ≤0.10 dB (premium), ≤0.20 dB (standard)

- Return Loss: UPC ≥55 dB, APC ≥65 dB

- Repeatability: ≤0.1 dB (1000 matings)

4.2 Mechanical Performance

- Mating Cycles: 500–1000

- Operating Temperature: –40°C to +85°C

- Vibration: 10–2000 Hz, 10 G

4.3 Environmental Performance

- Humidity: 95% RH non-condensing

- Dust Protection: IP54 (panel-mount)

4.4 Compliance Standards

- IEC 61754 (connector interfaces)

- Telcordia GR-326 (reliability)

- RoHS/REACH (environmental)

- UL 94 V-0 (flammability)

- TIA/EIA-604 (FOCIS)

CommMesh adapters achieve ≤0.08 dB IL and ≥68 dB RL (APC).

5. Applications Across Industries

5.1 Data Centers and Enterprise

- LC adapters for high-density 400G/800G panels.

- MPO adapters for parallel optics breakouts.

5.2 FTTH and PON Networks

- SC/APC adapters in termination boxes and closures.

5.3 Telecom and Backbone

- FC adapters for test equipment.

- SC adapters for central offices.

5.4 Industrial and Harsh Environments

- E2000 or ruggedized SC for factories.

5.5 Broadcast and CATV

- SC/APC for analog video.

5.6 Test & Measurement

- FC adapters for precision instruments.

6. Installation Best Practices and Handling Tips (Expanded)

6.1 Preparation Before Installation

- Inspection: Use 200×–400× inspection scope to check endface for scratches, contamination, or chips.

- Kusafisha: Use one-click cleaner (type A for 1.25 mm, type B for 2.5 mm) on both connectors and adapter sleeve.

- Mazingira: Work in clean area; avoid dust.

6.2 Mating Process

- Remove dust cap carefully.

- Align keying (APC notch must match).

- Push firmly until click (SC) or latch engages (LC).

- Avoid twisting or forcing.

6.3 Torque for Threaded Types

- FC/ST: 0.9 N·m (use torque wrench).

- Over-tightening damages ferrule.

6.4 Safety Considerations

- Never look into live fiber.

- Use shuttered adapters for live systems.

- Label polarity and type.

6.5 Common Mistakes and Fixes

- Mixing UPC/APC → severe reflection → replace immediately.

- Contamination → clean both ends and sleeve.

- Loose mating → re-seat or replace.

7. Cost Analysis and Pricing Trends 2026 (Expanded)

7.1 Upfront Pricing

| Type (duplex) | Price Range USD | Bulk (10k+) Discount |

|---|---|---|

| SC UPC Simplex | 0.80–1.50 | 40–60% |

| LC APC Duplex | 1.20–2.00 | 45–65% |

| MPO 12-fiber | 5.00–8.00 | 50–70% |

| Hybrid SC-LC | 1.80–3.00 | 40–55% |

7.2 Total Cost of Ownership Factors

- Initial price

- Failure rate (poor quality = 5–10% failure vs premium <1%)

- Maintenance (cleaning, replacement)

- Downtime cost

7.3 Procurement Strategies

- Direct from manufacturers for 30–50% savings.

- Request sample testing.

- Prefer suppliers with full traceability and OTDR reports.

8. Common Pitfalls and Troubleshooting Techniques (Expanded)

8.1 Most Frequent Issues

- Uchafuzi: Dust or oil on endface → 0.5 dB loss. Fix: Clean with one-click and inspect.

- Polish Mismatch: UPC to APC → –35 dB RL. Fix: Replace with correct type.

- Loose Mating: Intermittent signal. Fix: Re-seat or replace spring.

- Over-tightening: Cracked ferrule. Fix: Use torque wrench.

8.2 Advanced Troubleshooting

- Use OTDR to locate high-loss point.

- Video inspection scope for endface analysis.

- Power meter for end-to-end loss.

9. Innovations and Trends 2026–2030 (Expanded)

9.1 Very Small Form Factor (VSFF) Adapters

- SN, MDC, CS connectors for 1.6T+ density.

9.2 Shuttered and Smart Adapters

- Automatic shutter for laser safety.

- RFID for inventory tracking.

9.3 Sustainable Materials

- Recycled plastics and biodegradable components.

9.4 Hybrid and Multi-Fiber

- More LC to MPO hybrids for breakout.

Conclusion: Mastering Fiber Optic Adapters for Future Networks

Fiber optic adapters are small but vital. Choose quality for performance.

CommMesh offers premium adapters — contact us.