Nguruwe za optic za nyuzi huunda viunganisho. Fikiria hizi kama waya maalum zilizotengenezwa kwa glasi, sio shaba. Nyaya hizi zina kiunganishi ambacho tayari kimewekwa kiwandani. Utapata mwisho mwingine wazi.

Unaweza kuunganisha mwisho huu kwa kebo nyingine ya nyuzi. Fiber optic pigtails husaidia kuunganisha sehemu mbalimbali za mtandao mkubwa unaotumia mwanga kutuma taarifa. Safu nyembamba, yenye nguvu, unene wa 900 µm pekee, hufunika glasi. Sehemu ya katikati, inayoitwa msingi, ni ndogo sana, ni 9µm tu kwa upana.

Karibu na msingi kuna safu nyingine inayoitwa cladding, na hii ni 125 µm. Unapojiunga, unataka mwanga mdogo sana upotee, chini ya 0.2 dB. Pia, tunataka kuhakikisha kuwa mwanga haurudi nyuma sana, ikiwezekana kuwa chini ya 55 dB. Nguruwe za optic za nyuzi hufanya kazi na aina maalum za mwanga, kipimo cha 1310 nm au 1550 nm wavelengths. Unaweza kuzitumia katika sehemu zenye baridi kali hadi -20°C na sehemu zenye joto hadi 70°C. Kiunganishi kilicho mwisho kimetengenezwa kwa nyenzo ngumu inayoitwa kauri.

Kuna njia tofauti za kung'arisha ncha, kama UPC. Pia kuna APC, ambayo ni bora zaidi katika kuzuia mwanga kutoka kwa kurudi nyuma. Hizi ni aina tofauti za nyuzi za glasi, kama OS2. Jalada la nje limetengenezwa kwa nyenzo kama vile PVC. Nguruwe za optic za nyuzi zinaweza kutuma ishara moja au nyingi za mwanga mara moja.

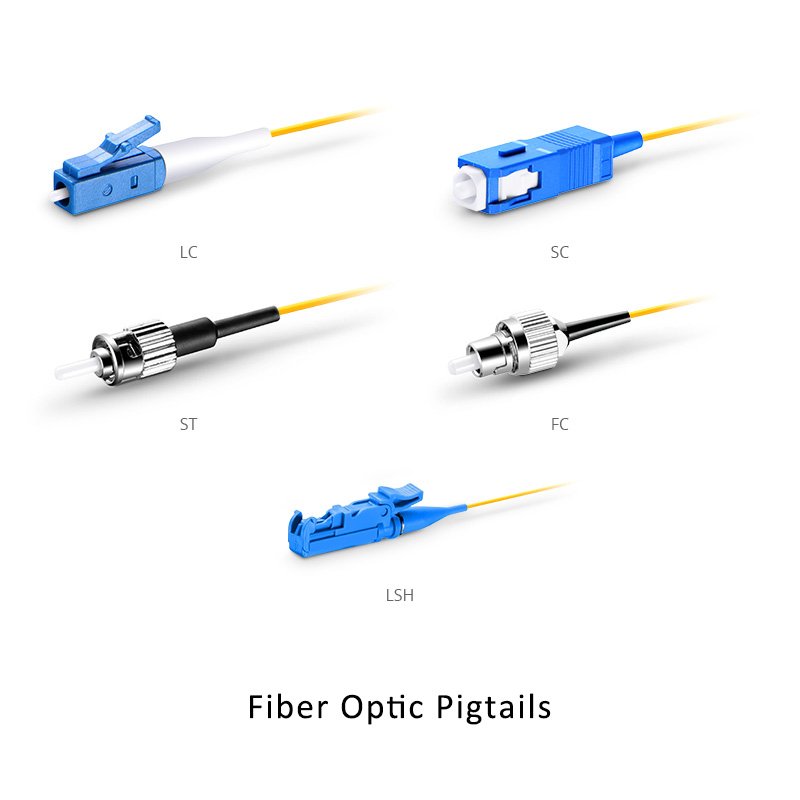

Nguruwe za Kiunganishi cha Msajili zina njia rahisi ya kuunganisha na kukata. Sehemu ya kiunganishi hurahisisha kuziba. Kipande kidogo cha pande zote ndani, upana wa 2.5 mm, huweka vitu kwenye mstari. Wakati wa kutumia pigtails hizi za fiber optic, mwanga kidogo tu hupotea, kuhusu 0.25 dB. Mwanga wa kurudi nyuma ni mdogo, karibu 50 dB.

Hizi hufanya kazi vizuri katika halijoto kati ya -40°C na 75°C. Zaidi ya hayo, unaweza kuzichomeka na kuzichomoa mara 1000. Kipenyo cha kivuko ni 2.5 mm. Hizi zinatengenezwa kwa kutumia nyuzinyuzi za OS2 za modi moja 9/125. Msingi umezungukwa na vifuniko vya 125 µm. Jacket imetengenezwa kwa nyenzo za PVC. Urefu wa kawaida ni mita 1. Bafa inayobana 900 µm hulinda nyuzinyuzi. Boot ya kupunguza mkazo huzuia kuinama.

Nguruwe za Lucent Connector zina viunganisho vidogo sana. Matoleo ya Kiunganishi cha Lucent ni nusu ya ukubwa wa yale ya Kiunganishi cha Msajili. Fimbo ndogo, upana wa 1.25 mm tu, iko ndani. Inapounganishwa, ni 0.1 dB pekee ya mwanga hupotea. Nguruwe hizi za fiber optic huonyesha mwanga mdogo sana nyuma, karibu 60 dB. Kwa kuongezea, wanaweza kuhimili joto kutoka -40 ° C hadi 80 ° C. Unaweza kuziunganisha na kuziondoa mara 500.

Hizi zinatengenezwa kwa kutumia nyuzinyuzi za OS2 za modi moja 9/125. Msingi umezungukwa na vifuniko vya 125 µm. Jacket imetengenezwa kwa nyenzo za LSZH. Urefu wa kawaida ni mita 2. Bafa inayobana 900 µm hulinda nyuzinyuzi. Boot ndogo ya kutuliza shida iko. Zinapatikana katika Kipolishi cha UPC. Hasara ya uwekaji ni chini ya 0.1dB. Zinaendana na IEC 61754-20.

Nguruwe za Kiunganishi cha Ferrule zina muundo maalum ambao hukuruhusu kuzifunga vizuri. Kwa hivyo, hii inahakikisha kuwa wanabaki wameunganishwa. Ndani, kuna kipande kidogo, cha mviringo ambacho kina upana wa 2.5 mm. Hasara ya mwanga ni ya chini sana, tu 0.3 dB. Pia, huzuia mwanga mwingi kutoka kwa kurudi nyuma, karibu 50 dB. Unaweza kutumia mikia hii ya nyuzi macho mahali ambapo ni kati ya -20°C na 70°C.

Zaidi ya hayo, ni nzuri kwa miunganisho 500 na kukatwa. Feri hufanywa kutoka kwa keramik ya zirconia. Hizi ni nyuzi za OS2 za mode 9/125. Kiini kina kipenyo cha 9 µm. Kipenyo cha kufunika ni 125 µm. Jacket hutumia nyenzo za PVC. Urefu wa kawaida unapatikana kwa mita 3. Hizi zinapatikana katika Kipolishi cha UPC na APC.

Nguruwe za Kidokezo Sawa zina kiunganishi ambacho unaweza kupotosha na kufunga kwa urahisi. Ipasavyo, hii inafanya kuwaunganisha rahisi. Wana sehemu ndogo ya pande zote ndani ya upana wa 2.5 mm. Zinapoteza tu takriban 0.3 dB ya mwanga wakati zinatumika. Nguruwe hizi za fiber optic huweka mwanga unaorudi chini, karibu 40 dB. Unaweza kuzitumia mahali ambapo ni kati ya -20°C na 60°C.

Zaidi ya hayo, unaweza kuunganisha na kuziondoa mara 500. Feri hufanywa kutoka kwa keramik ya zirconia. Aina ya nyuzi ni OS2 single-mode 9/125. Kiini kina kipenyo cha 9 µm. Kipenyo cha kufunika ni 125 µm. Jacket imetengenezwa kwa nyenzo za LSZH. Wanakuja kwa urefu wa mita 1, 2, au 3. Urefu wa wimbi la uendeshaji ni 1310 nm au 1550 nm.

| Vipimo | Kiunganishi cha SC | Kiunganishi cha LC | Kiunganishi cha FC | Kiunganishi cha ST | Kigezo | Teknolojia ya Kusafisha |

| Kipenyo cha Ferrule | 2.5 mm | 1.25 mm | 2.5 mm | 2.5 mm | Kipenyo cha Msingi | UPC |

| Hasara ya Kuingiza | 0.25 dB | 0.1 dB | 0.3 dB | 0.2 dB | Kipenyo cha Kufunika | APC |

| Kurudi Hasara | 50 dB | 60 dB | 55 dB | 40 dB | Urefu wa mawimbi | Zirconia |

| Joto la Uendeshaji. | -40 hadi 75°C | -40 hadi 80°C | -20 hadi 70°C | -20 hadi 60 ° C | Kipenyo cha Bafa | Kauri |

| Mizunguko ya Kuoana | 1000 | 500 | 500 | 500 | Nyenzo ya Jacket | LSZH |

| Aina ya Fiber | OS2 9/125 | OS2 9/125 | OS2 9/125 | OS2 9/125 | Nguvu ya Mkazo | PVC |

| Urefu wa Kawaida | 1 m | 2 m | 3 m | 3 m | Halijoto ya Kuhifadhi | 9µm |

Weka nafasi yako ya kazi ikiwa nadhifu. Hakikisha eneo unaloanza kufanyia kazi ni safi kabla ya kuanza: hii itazuia uchafuzi wa nyuzi 900µm. Kutumia vifuniko vya ubora vya nyuzinyuzi hudai unadhifu wa nafasi ya kazi. Angalia urekebishaji wa mita ya nguvu ya macho kwa 850nm, 1300nm, 1310nm, 1550nm. Unapaswa pia kuthibitisha angle ya digrii 8 ya kiunganishi, pamoja na uthibitisho wa upatanishi wa elektrodi wa kuunganisha.

Vua kwa uangalifu mita 1, bila kuharibu msingi wa 9µm. Baadaye, unaweza kuweka kivuko cha mm 2.5 kwenye v-groove. Kupata chini ya 0.05dB hasara, panga, kutekeleza 10 splices. Kwa hiyo, linda kila kiungo kwa kutumia sleeve ya 60mm.

Bila ubaguzi, kutumia zana ya 1.25mm kwa viunganisho vya LC itakuwa muhimu. Kisha, kwa uunganisho wa SC, tumia fimbo ya 2.5mm, ukigeuka nusu. Kwa matokeo bora, shughulikia vifuniko vya nyuzinyuzi kwa kutumia zana zinazofaa. Unapaswa kutoa kiasi cha pombe cha 2ml, ukitumia wipes 4x4-inch. Kwa aina za FC, washa kisafishaji cha mbofyo mmoja mara tatu.

Kufuatia usanidi, funga kila pigtail ya fiber optic ndani ya rack ya inchi 19. Kisha, pointi za kuunganisha zinaweza kuingizwa katika sleeves 45mm. Kutumia misimbo ya rangi kwenye nyaya za nyuzi 0.9mm ni muhimu. Kisha, lazima uhifadhi vitu ambavyo havijatumiwa, kuhakikisha unyevu unabaki chini ya 40%.

Mawasiliano Haraka

Ili kuokoa muda wako, tafadhali wasiliana nasi kwa haraka kupitia fomu iliyo hapa chini ili kupata nukuu ya papo hapo.